/

5/4/2023

Cordys Capital logistics centre

High-strength polymer fibers to withstand high volumes of goods-handling traffic.

High-strength polymer fibers to withstand high volumes of goods-handling traffic

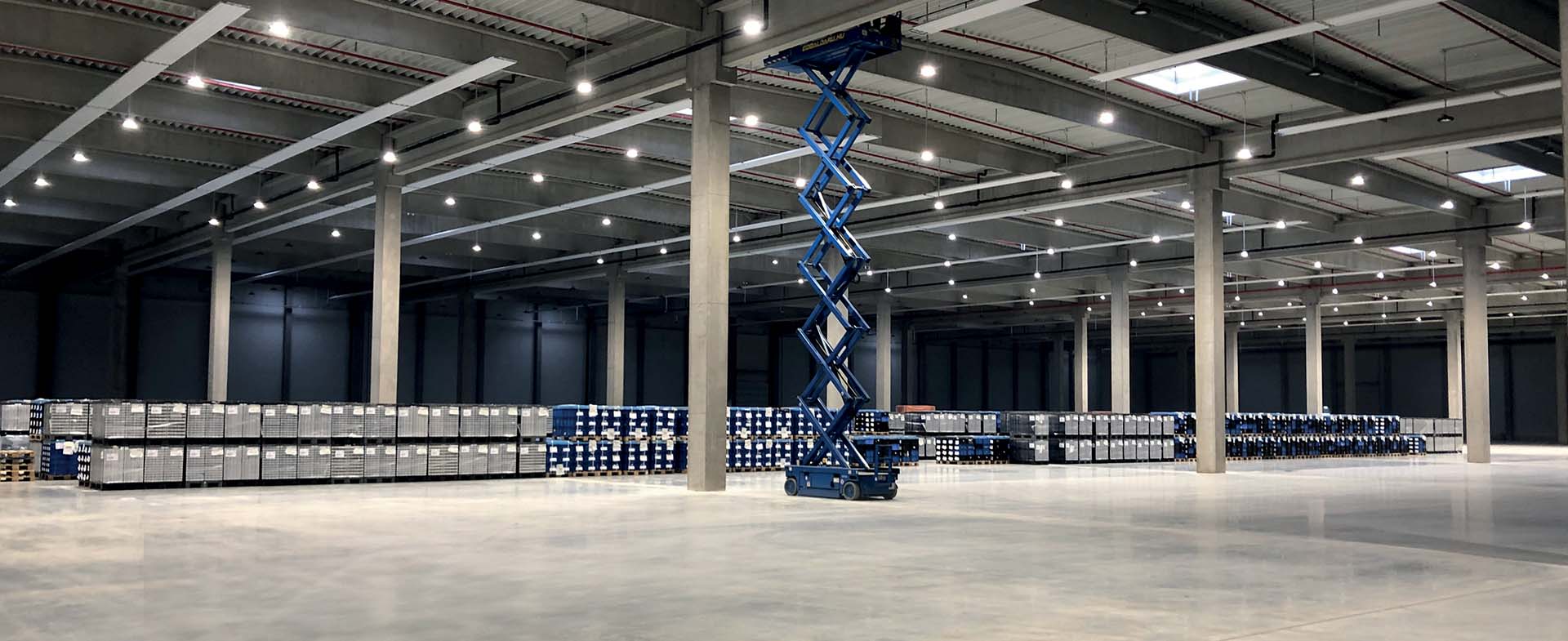

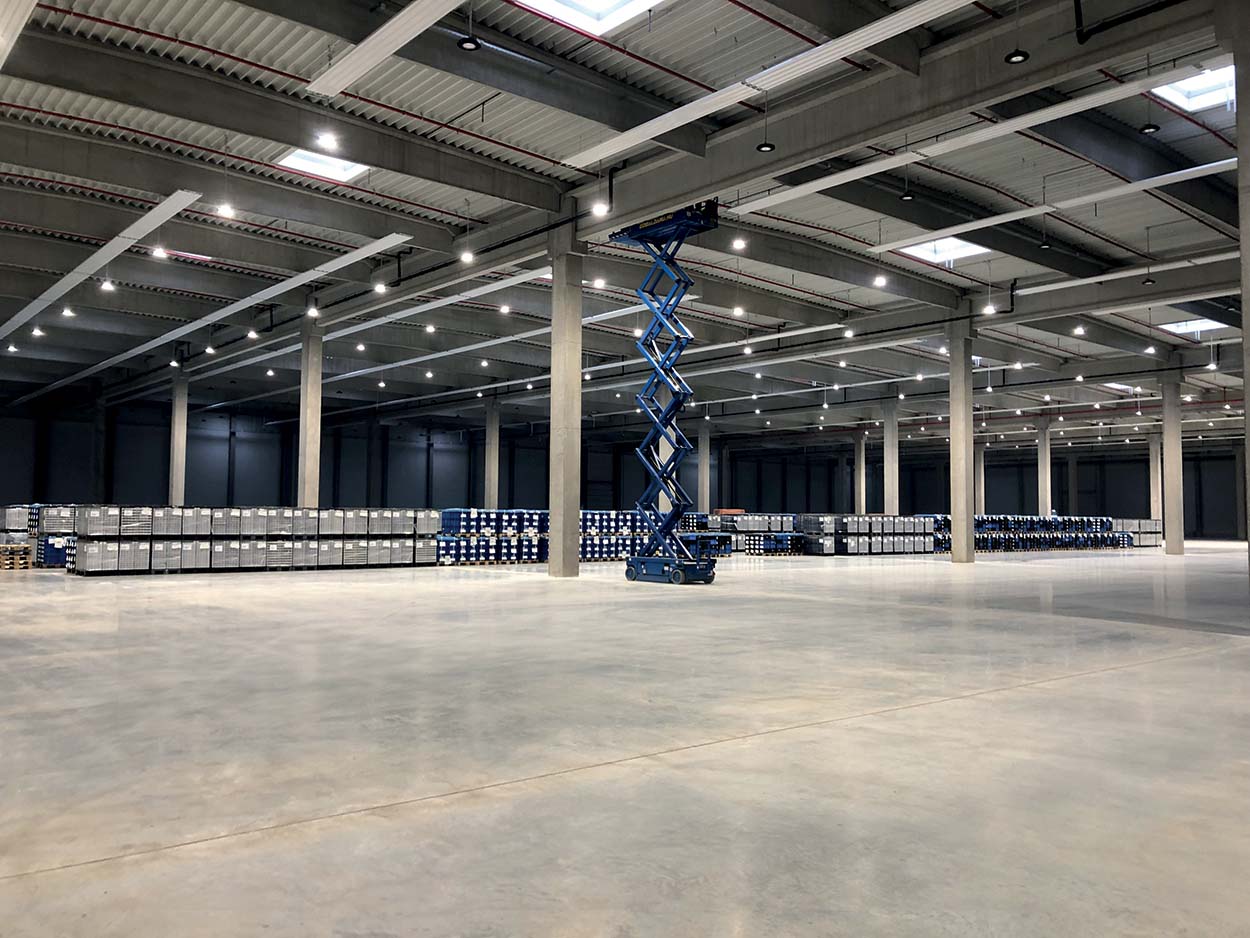

A new logistics hub with high performance concrete floors

The city of Szirmabesenyő is in northern Hungary in the Borsod-Abaúj-Zemplén County which, apart from being a popular tourist destination thanks to its local gastronomic delicacies and outstanding natural beauty (two local sites have been designated UNESCO World Heritage sites), the local economy is also going through a period of growth. For Hungarian investors conditions are particularly favourable to launch new projects, which is why Cordys Capital, a real estate company specialised in the logistics sector, chose the area for a new 25,000 m2 logistics hub.

MAPEFIBRE ST 50 TWISTED fibers allowed to create a jointless concrete floor without having to use steel mesh.

A floor up to the task

The complex, construction of which was completed at the end of 2022, consists of a reinforced concrete frame structure covered with masonry panels.

Apart from erecting 192 columns to support the roof structure, the main contractor, Perfect Construct Ltd, wanted to install a floor that would guarantee excellent performance properties, mechanical characteristics, and durability, to be in line with the overall build quality, and withstand the high volume of traffic expected for handling and moving goods.

An innovative and functional solution needed to be found and Perfect Construct Ltd turned to Mapei Kft., who proposed a complete system for the construction of fiber-reinforced concrete floors.

Rather than use steel fibers, as specified in the original project, the experts from Mapei Kft. proposed the use of high strength polymer fibres, in this case MAPEFIBRE ST 50 TWISTED, which were added during the mixing phase of the concrete along with DYNAMON SR31 super-plasticising admixture and MAPECURE SRA curing admixture

The fibers enabled the steel reinforcement to be eliminated, but still guaranteed a high level of ductility and toughness for the concrete, while the admixtures enabled the concrete to maintain its workability for a long time, made it easier to place and helped maintain its high mechanical performance properties and, at the same time, reduced hydraulic shrinkage and the risk of the formation of micro-cracks.

Once the concrete floor had been placed, the finishing treatment was carried out with MAPETOP N AR6 ready to use, pre-blended dry shake hardener which, thanks to its high strength and resistance to abrasion, is particularly recommended to create anti-wear layers for concrete floors in industrial and commercial environments.

Once the surfaces had been treated, the final step was to prevent evaporation taking place too quickly by applying MAPECURE E30, a film-forming curing agent in water solution that helps provide more resistance to wear and reduces the amount of dust that forms on the surface of floors.

Thanks to this specific Mapei system, a jointless floor was created within several pitches, each measuring 500 m2. This solution met with full approval of the flooring contractor, which was able to create a surface free of cracks and without having to move joints despite the extensive pitch areas.

Thanks to the excellent results achieved, it was later decided to use the same system for the external concrete floors.

Thanks to a specific Mapei system, the floor features no joints within pitches, each measuring 500 m2 .