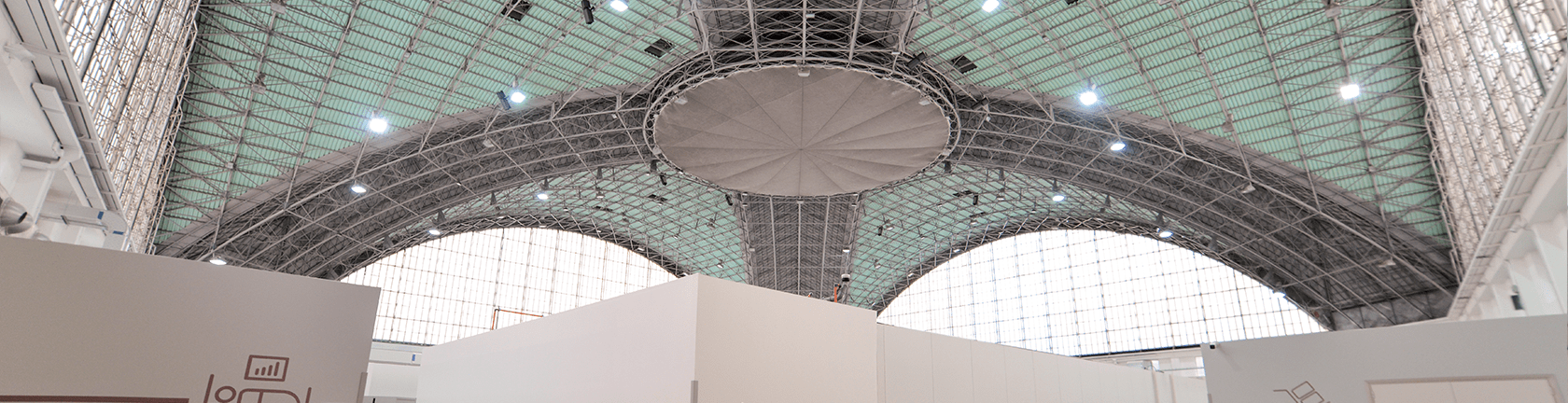

Fiera del Levante Covid Hospital in Bari (Italy)

“Fast-Track” installation systems adopted to create three pavilions with 152 intensive care beds in in just 45 days.

“Fast-Track” installation systems adopted to create three pavilions with 152 intensive care beds in in just 45 days.

Built in record time – work started on December 1st and was completed after 45 days at the Fiera del Levante exhibition centre – the new Policlinico di Bari Hospital will be directly responsible for the running of the new structure’s intensive care and post-intensive care units.

Apart from Mapei, more than 40 other companies took part in the work to prepare 10 wards over an area of around 15,000 m2, along with 2 operating theatres, a TAC and x-ray centre and a clinical laboratory. The hospital hosts 10 intensive care units with 16 beds each, which will be taken apart and used again once the emergency is over. The first patients were transferred at the beginning of February and the Covid centre was put into service.

ULTRA-RAPID INSTALLATION AND DURABILITY OVER THE YEARS

The floor and wall coverings installed in the new hospital were all supplied by Tarkett: Tapiflex Genius multi-layered vinyl floor for most of the surfaces, Primo SD static-dissipative vinyl floor in the operating theatres, Primo Safe T homogeneous vinyl floor in the bathrooms, as well as Wallguard homogenous vinyl covering and Aquarelle heterogeneous vinyl covering for the walls. Amongst the adhesives recommended to install these coverings, the main ones were ULTRABOND ECO V4 EVOLUTION universal adhesive in water dispersion, ULTRABOND ECO FIX pressure sensitive adhesive and MAPECONTACT double-sided reinforced adhesive strip.

RESIN FLOORS AND COATINGS

The forecourt used as a waiting area for ambulances with an old industrial-type concrete floor substrate with no vapour barrier was mechanically prepared by diamond grinding treatment over the MAPEFLOOR SYSTEM 51, an opaque, multi-layered, vapour-permeable epoxy coating system in water dispersion. The product chosen to finish off the walls in the new hospital was MAPECOAT ACT 196, an enamel paint for interior walls, highly washable and resistant to bacterial attack, containing protective, wide spectrum biological agents to contrast the spread of bacteria on surfaces. Because different types of surface needed to be painted, they had to be treated beforehand with DURSILITE BASE COAT coloured smooth acrylic base coat to even out their absorption and form a more uniform layer.

INSTALLING CERAMIC TILES

120x60x1 cm ceramic tiles were installed in the administration-managerial area on the first floor of the complex.

The ceramic tiles were bonded using KERAFLEX EXTRA S1 cementitious adhesive, while the joints were grouted with ULTRACOLOR PLUS mortar and the expansion joints were sealed with MAPESIL AC.

"It was an extremely intricate project”, so the Site Director Mr. Festa added, "cutting-edge products were chosen for this building project so that such an important work could be completed on a very tight schedule."

.jpg?sfvrsn=64acf171_4)

.jpg?sfvrsn=50acf171_4)

.jpg?sfvrsn=52acf171_4)

.jpg?sfvrsn=58acf171_2)