From Rocks to Rheology

Understanding the role of morphology in manufactured sand for concrete

In the past three decades, the construction industry has seen a clear shift from depleting resources of natural sand to replacing them with manufactured or recycled aggregates. Fine aggregate, i.e. sand, has a major impact on the behaviour of the concrete, particularly in the fresh state. Admixtures are playing a vital role in mitigating the challenges that these new sands are bringing. The main challenge areas are sorption- the tendency of particles to absorb and adsorb moisture- and morphology- the geometrical properties of aggregate.

The morphology of sand offers a valuable framework for understanding both the behaviour of individual particles and the mass effect of many particles of different shapes and sizes in a concrete mix. Understanding morphology also enables better engineering of concrete admixtures — helping formulators counteract the challenges that inevitably follow when changing from natural to manufactured sand.

From a sustainability point of view, the morphology has a major impact on the environmental footprint of concrete as a building material. One aspect of sustainability concerns how society, and particularly the concrete industry, can reduce the exploitation of limited raw material resources. The transition that is occurring in many markets, with increased usage of manufactured sand as replacement of natural sand is one example. However, by only changing from a natural sand to a manufactured without any attention to morphology, there is a risk of creating one environmental problem, ie, increased cement demand, leading to higher CO2 emissions, by trying to solve another. In this way, carbon footprint and natural resource management is interconnected by the concept of morphology.

The aspects we will explore further in this article are particle shape, particle size distribution and surface texture. There are two reasons for this: Firstly, they affect greatly the properties of sand when it comes to cement paste demand in concrete mix design. Bad performance in any of the three aspects can lead to:

- Poor packing, causing high percentage of voids in the sand mix, and hence a high initial cement paste demand

- High specific surface area, also leading to increased paste demand.

- Rough particle edges leading to higher voids content and more cement paste needed for particle coverage.

- Poor mobility, due to rough edges and flaky particles interlock and increase internal friction. This leads both to a higher required force to initiate flow (also known as yield stress) and to higher plastic viscosity, i.e. the ability for continuous movement

- Poor Finishability. Flaky particles are prone to protrude through the surface, and the concrete texture becomes harsh.

- Reduced pumpability, by increasing line friction, pump pressure and reduced ability to use smaller hose dimensions and longer pumping distances.

Particle packing density and paste demand

Interaction between the aspects of particle shape, particle size distribution and to some extent the surface texture will result in a fine aggregate mix that will require a certain volume of cement paste to meet the requirements of the concrete for a given specification or mix design. The paste demand is related to the three particle based aspects. But rather than to look at the particles themselves, we need to study the empty space between them that are created when they are loosely packed together. We call this the "voids content" or "particle density".

By filling a container with loosely packed aggregate, we will get a mix of particles and air. These pockets of air are also defined as “voids”. Depending on the three factors, the sum effect of the particle shape, surface texture and particle size distribution will result in a particular voids content, which in a real situation corresponds to the volume of cement paste needed to fill all the voids and create a homogenous mass or volume. We sometimes refer to this state as the “zero-slump” concrete, because in this state, there is no surplus paste/matrix available to create fluidity in the concrete.

Combination of particle shape and texture for cover and movement in fresh concrete

Secondly, the amount of space or free volume space each particle needs to move within the concrete also differs. Of course, the total paste demand is not the sum of all this individual “wiggle room,” since particles are packed much more closely together in an actual concrete mix. Nevertheless, the illustration below explains the principle that particles with poorer shape characteristics increase the paste (or matrix) demand of the mixture to allow the movement and flow characteristics required.

Cement paste need as a function of specific surface area of sand

By breaking a particle into smaller and smaller pieces we will increase the surface area per weight unit since more exposed surfaces will appear with each cleavage. The figure below is based on an idealized geometric model for perfect cubes. It shows that by splitting an original cube once in each plane, i.e. into 8 pieces, the specific surface area doubles. Again, when we have split the original size (weight) particle into 64 pieces, the surface area is now 4 times higher.

This theoretical model is a way to understand why increased fines content leads to higher paste demand. Manufactured sand very often have a higher content of particles in the size ranges from 63-250 microns if we compare with an ideal natural sand. Thus, the volume needed to coat all particles in the aggregate phase will also be higher.

Geological factors: rock groups and rock types

This distribution explains why limestone and dolomite dominate global aggregate production: they are widely available, easy to quarry, and versatile across applications. Granite, basalt, gneiss, and sandstone are also key contributors, chosen where local geology provides large, accessible deposits. Each rock type has its own mineralogy and fracture behaviour that influence not only quarrying and crushing efficiency, but also the morphology and performance of the manufactured sand and aggregates they produce.

Geological factors: Fracture mechanics

Main principles of crushing

Impact crushers, by contrast, fracture rock using kinetic energy, typically through one of two mechanisms: either rotating hammers within a chamber into which the rock is fed, or a vertical shaft impeller that accelerates particles outward into a crushing chamber. In this chamber, particles collide with each other at high velocity—transferring kinetic energy and causing breakage along natural planes, attrition at sharp corners,and surface polishing through grinding.

When it comes to manufactured sand, particle shape and fines generation are the two governing factors in the choice of crusher type. The illustration below can serve as a general description of the crushers effect on particle shape, where the purple dotted lines represent the typical fracture pattern (Remember the inter-relation withrock type fracture mechanism!).

Compression crushers add crushing forces from a moving metal surface into the rock particles. This tends to fracture the rock in elongated and flaky particles. Horizontal shaft impact crushersuse a rotating hammer and kinetic energy. As the particles collide with the metal curtain, fracture normally takes place along the weakest plane. Elongated particles break at their smallest dimension, forming more cubical shape. Autogenous impact crushers use the kinetic energy caused by acceleration in a rotor. Particles fracture in the weakest plane. In addition, attrition takes off sharp corners and grinding along the rock bed polishes the particlesinto a more rounded shape. Rock on rock crushers normally produces the best particle shape, but at the cost of slightly higher fines generation, affecting the PSD and in extension, the specific surface area increases.

Most experts agree that “rock-on-rock” crushing mechanism is especially effective for hard and abrasive rocktypes when the goal is to produce high-quality manufactured sand with optimal particle shape at a relatively low energy consumption in kWh/ton. I have personally seen many successful applications of this type of Rock on rock (VSI) impact crusher in production of manufactured sand. One of its strengths is the ability to finetune crushing and shaping action by altering the speed of the rotor. This way, the optimum kinetic energy level can be applied tothe rock type in question, to balance between producing good particle shape and at the same time trying tomitigate over-production of superfines. With the help of a frequency converter on the electric drive motor, the optimum rotor speed-and kinetic energy input can be selected in accordance with the fracture mechanism of therock type being crushed.

From theory to practice: Testing morphology of sand and applying admixtures

In concrete mix design, it is always welcomed to have test methods that can predict and quantify the morphological aspects discussed above to also predict concrete behaviour and benchmark the performance and paste demand for different types of sand.

The two resulting parameters — flow time and voids content — are plotted together, where the empirically established “experience envelope” serves as an indicator of expected paste demand and workability performance. There are also other methods for investigating the rheology of mortar and concrete containing sand of varying morphology.

Once the morphology is known, different actions can be taken by the concrete mix designer to achieve the optimum performance in concrete. Let us look at a few practical scenarios:

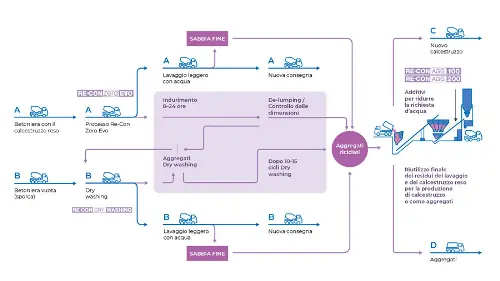

A) High amount of fines particles. This is a common situation when dealing with manufactured sand. The high surface specific surface area will bind water and cement paste and may cause rapid slump loss. Absorption inhibiting admixtures like those belonging to the Re-Con AGG range can mitigate this problem.

B) Lack of particles in the 250-500 micron range. This is again a common characteristic of manufactured sand. The inherent mineral grain size(s) of the rock type combined with the crushing mechanism can result in a PSD that is deficient in the above-mentioned range. This may become critical when designing Self Compacting Concrete or similar concrete types that require high fluidity. Small variations in production can lead to concrete separation. Admixtures that can remedy this problem are viscosity modifying agents, one example being Viscostar 3K.

C) Excess or poor particle shape of particles 2-8 mm. This area of the PSD governs the initial paste demand based on voids content as described earlier. It can also affect finishability and pumpability. In mix design that requires pumping, Mapepump Oil can lower pump pressure and increase flowability. All of the admixtures can be used in combination with the superplasticizers in the Dynamon and Chronos range, enhancing or complementing their function in the mix design.

All of the above factors (morphology, geology, crushing methods, etc.) have a significant impact on the use of manufactured sand in concrete production. If you would like to find out more, you can read the full, detailed version of this article, which is available as a PDF in the contents related to this article.