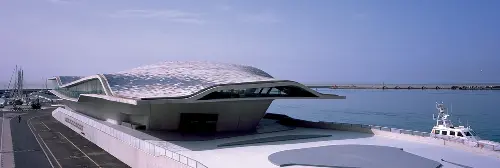

Naples Afragola Station

International spotlight for the opening of the Naples Afragola High-Speed Railway Station.

Naples Afragola Railway Station was designed by Zaha Hadid Architects and was put by CNN news network on the list of highly anticipated works of 2017. Mapei helped construct it by supplying its products.

After two years of work and a contract worth around 600 million Euros, the Naples Afragola Railway Station was inaugurated by the Italian Prime Minister, Paolo Gentiloni, on the 6th of June. Because the station plays a strategic role in linking the north and south of the Italian peninsular, it is also known as the Gateway to the South. Apart from being a fine example of contemporary architecture and a strategic hub for the regional and national high speed railway network, Naples Afragola is an important opportunity to integrate the urban areas of the local territory with the world of transport.

Once it is working at full capacity, thanks to its future connection with the Circumvesuviana line, the hub will serve a catchment area of around 3 million potential users from North part of the whole region.

The station is the result of an international design contest with which the national railways group FS Italiane, through its subsidiary company RFI (Rete Ferroviaria Italiana), intended to launch a new era in large-scale architectural railway projects in Italy. And 14 years after launching the four different contests for four different cities, the project can be considered on the road to completion following commissioning of the stations of Turin Porta Susa HS, Rome Tiburtina and Naples Afragola, with just Florence Belfiore missing from the role-call.

FUNCTIONAL AND MODERN: HOW A NEW STATION IS BORN

The station was designed by the British architect of Iraqi origin Zaha Hadid, who passed away in 2016 and carried out by Astaldi Group. It has sinuous lines similar to a train in motion and the CNN news network put it on the list of highly anticipated works of 2017.

The overall length of the central body of the station is 400 metres and, like a large bridge, straddles the platforms and connects the areas crossed by the railway lines, giving a sense of continuity between the surrounding landscape and the railway lines. The building of the station itself is characterised by large windows supported by steel and concrete walls that sit flush with the Corian dressing, a composite material made from acrylic polymer and alumina trihydrate (ATH), creating an effect of continuity between the opaque and transparent walls. The structure covers an area of more than 30,000 m2, rises to a height of 8 metres above the level of the tracks, slopes away at the ends and is developed over 4 levels.

The first level is for the movements of the trains themselves which, during the first phase, will use four of the available platforms: two for arrivals and departures and two for the trains that do not stop at Naples Afragola. A further two platforms will be put into service during the second phase and they will be used for regional trains and for the extension to the Circumvesuviana line. On the second level of the station are the ticket offices and hospitality lounges of the railway company, which will provide various services for passengers in the new station. The third and fourth levels will be phased in shortly with shops and other commercial services available for the passengers.

A large glass cover of more than 6,000 m2 was designed and installed on the roof of the station. The external area of the station will be 150,000 m2 with gardens and a car-park for around 500 cars, which upon completion of the project will be extended to accommodate 1,400 cars. There will also be a taxi rank for 53 vehicles, a dedicated kiss&ride drop-off lane (free parking places for quick stops) and a bus terminus with 8 bays, which will then also be extended to 15 bays. Completion of the second phase and of the functional works for the commercial services will be gradually phased in over the coming years.

ARCHITECTURAL CONCEPTS AND LANGUAGE ACCORDING TO ZAHA HADID

Naples Afragola is a concrete example of a new concept in rail travel, in which the station is no longer just an arrival and departure point for trains, but forms part of a more far reaching concept of mobility, with roots in the urban fabric in which it is located. This was intended by the Zaha Hadid Studio to act as a catalyser in the redevelopment of a highly urbanised territory located at the gateway to Naples. Designing a bridge-like structure over the tracks allows trains to have quicker stops, creates a more fluid internal distribution of traffic and, from an architectural point of view, guarantees a more rational use of spaces and the opportunity to use the main body of the station as a visual reference point for the flat landscape. The entrances are positioned at the two ends of the bridge-like structure so that the west entrance, which points in the direction of the city of Afragola, is close to the terminus of the public transport system, the car-park and access to the high-speed railway lines, while the east entrance is in correspondence with the access to the central part where the areas for the employees of the station are located.

Also, from a technological point of view, the layout of the bridge allows the main body of the building to be oriented according to best practices in sustainability. Solar panels integrated into the projecting roofs, combined ventilation and integrated cooling and heating systems all help to reduce the amount of energy required over the year.

The construction technology adopted, on the other hand, may be summarised into three main sections: reinforced concrete for the base and glass panels for the roof over the commercial and shopping gallery, while for the raised structure, the external shell of the building (around 20,000 m2) supported by around 200 specially-shaped steel columns, is made from concrete and Corian, a material chosen for its high performance properties in these particular atmospheric conditions and its exposure to chemical agents. To increase the level of comfort in the station, allow natural light to enter from above and improve visibility in the station to help passengers find their way around, the internal walls are mainly in glass, while the artificial lighting is mainly by LED to guarantee higher efficiency from the lighting.

MAPEI INTERVENTION

Mapei Technical Services was also contacted right from the very start of the project for the new infrastructure to provide support for the work carried out on site and to work alongside the main contractors, Astaldi, the Works Director and the Zaha Hadid Studio. To complete the work on Naples Afragola station, the work was divided into two phases. Phase 1 involved the commissioning of the High Speed service area of the station and the level 2 of the building where the commercial services and the west entrance are located, while the east entrance will continue to be used as the entrance to the site until at least the end of this year. Phase 2 involves completion of all the work connected to the project for the Naples/Cancello link, which is scheduled to be completed in 2022.

As far as Phase 1 which is discussed in this article is concerned, Mapei systems were used for the construction and installation of the external shell and for the floor coverings installed inside the station. Floor coverings have been installed up to Level 1 and most of Level 2, apart from the east gallery, while Levels 3 and 4 have been left in a semi-finished condition for the present time. The areas open to the general public have been cordoned off from the ones that are still closed by installing temporary barriers with a similar finish to the original ones, so that the station can remain fully operative, safeguard the overall architectural uniqueness of the structure and allow for a more rational use of the commercial areas.

The façades of the building are in exposed concrete and, initially, Mapei Technical Services suggested repairing and levelling off the surfaces where required with MAPEGROUT T60 fibre-reinforced, sulphate-resistant thixotropic mortar and MAPEGROUT LM2K two-component, fibre-reinforced, thixotropic cementitious mortar mixed with corrosion inhibitor. To seal the cracks in the surfaces it was recommended to apply EPORIP two-component, solvent-free epoxy adhesive.

Once this phase had been completed, the delicate job of skimming the façades could commence. After discussing the opinions and specific requirements of the client, the Works Director, the contractor (Astaldi) and the artistic director (the Zaha Hadid Studio), Mapei R&D laboratories worked from June to December 2016 to develop a product with the required characteristics: PLANITOP FINE FINISH. This product is a light grey coloured one-component, ultra fine-textured cementitious skimming compound which, thanks to its special composition, gives the mortar a particularly high level of adhesion and excellent flow during application. Once the substrate was cured, it was initially treated with MALECH micronized acrylic resin-based primer, which is used to even out the absorption of substrates and promote a better bond with the layer of paint applied afterwards. The entire surface was then painted with COLORITE BETON semi-transparent, anti-carbonation paint in the colour RAL 9984 to even out the surface, which was also specifically developed. The paint forms a semi-transparent film which leaves the effect of the formwork or the exposed finish of the building visible and evens out its colour.

COLORITE BETON has a special formulation that protects surfaces over the years from damage caused by carbon dioxide, sulphur dioxide and direct sunlight and ensures good water-repellence.

In certain areas of the station such as the platforms, up to a level of 1.5 metres above ground level, the walls were protected against scuff marks and scratches with WALLGARD GRAFFITI BARRIER paint.

To form the resin floors inside the station (around 8,000 m2), Mapei Technical Services suggested using MAPEFLOOR SYSTEM 31. This system is particularly recommended for floors areas where a multi-layered, non-slip resin coating with excellent mechanical properties and excellent resistance to chemicals and abrasion is required. The coating was formed by priming the floor with MAPEFLOOR I 910 epoxy binder and then applying a layer around 0.8 mm to 1.2 mm thick of MAPEFLOOR I 300 SL two-component, solvent-free, fillerized epoxy formulate. Where required, some of the areas were treated with MAPECOAT I 600 W two-component, epoxy resin-based-formulate. For some of the work on the roof, Mapei Technical Services proposed using waterproofing membranes made by POLYGLASS, a subsidiary company of Mapei Group.

The collector channels for the rainwater on the metal roof were coated with white, high-reflectance MAPEPLAN T B flexible, waterproof polyolefin membrane.

The membrane was bonded to the metal sandwich support panels with MAPEPLAN ADS 300 adhesive. The waterproofing work was carried out in two phases. The first phase was to pre-waterproof the collector channels prior to installation in the Carrara works, which was carried out by the specialised company contracted to carry out the work. The second phase was the actual installation of the collector channels on site and then to blend in and finish off the waterproof membrane.