Re-Con Zero Evo: the keystone for sustainable concrete in Japan

Despite being the most used material in the world and despite offering manifold advantages, concrete may have crucial consequences. Firstly, the complex question of waste management and the deriving disposal costs.

New ecological concrete, recycled concrete, sustainable industry - these are frequent topics nowadays. How is it actually possible to significantly cut the costs of disposal and, at the same time, of the consumption of natural resources?

Giorgio Ferrari, from the Research & Development Laboratories of Mapei SpA, tells us how Mapei's RE-CON ZERO EVO allows you to completely avoid landfilling and, at the same time, how it lets you transform, in few minutes of mixing and without any waste production, returned concrete into aggregates, which can be totally recovered and recycled to produce new concrete.

Together with NR-MX, a Japanese company, an innovative products has been formulated: discover the advantages of ECON.

Concrete, with more than 23 billion tons produced every year, is the most widely used material in the world. This is due to its exceptional characteristics: wide availability, inexpensiveness, possibility to form any kind of geometric shapes in the fresh state and to harden in strong and durable structures. Nevertheless, the production of concrete implies several drawbacks related to the consumption of natural resources, carbon emissions and waste production.

Concrete, with more than 23 billion tons produced every year, is the most widely used material in the world. This is due to its exceptional characteristics: wide availability, inexpensiveness, possibility to form any kind of geometric shapes in the fresh state and to harden in strong and durable structures. Nevertheless, the production of concrete implies several drawbacks related to the consumption of natural resources, carbon emissions and waste production.

EXCESS CONCRETE MAY TRANSFORM INTO WASTE

One of the biggest problems in terms of waste is returned concrete. This is the residual unset concrete that, for different reasons, is not used at the jobsite and comes back to the ready-mixed concrete plant inside the truck mixer. One of the reasons for returned concrete is that costumers prefer to order an excess of concrete in order to avoid shortage during construction; in other cases, the fresh delivered concrete might not meet the quality specifications (consistency, temperature, time of delivery) and it is rejected by the costumer.

The amount of returned concrete in industrialized countries varies from 2 to 3% of the overall concrete production; this means that, every year, from 500 to 700 million tons of concrete are not used and come back to the ready-mix concrete plants with the truck mixers; in most cases, it becomes a waste, representing a serious environmental problem at the plant.

FROM REFUSAL TO A NEW LIFE: AN ADMIXTURE CAN TRANSFORM RETURNED CONCRETE DIRECTLY FROM MIXER TRUCKS

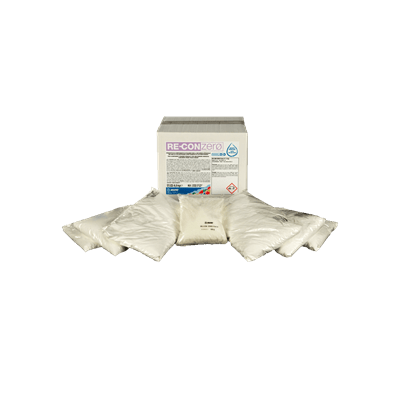

In 2012 Mapei developed RE-CON ZERØ, followed by the next generation product RE-CON ZERO EVO, a bi-component powder additive to recover returned concrete. By adding RE-CON ZERO EVO to the truck mixer, it is possible to transform, in few minutes of mixing and without any waste production, returned concrete into aggregates, which can be totally recovered and recycled to produce new concrete.

RE-CON ZERO EVO is the most sustainable system to recover returned concrete, because landfilling is completely avoided and, with the “in-house” production of 2.3 tons of aggregates from 1 m3 of returned concrete, quarrying is reduced and natural resources are preserved. The economic saving arises from the total cut of the disposal costs and the reduction in the supply of virgin aggregates.

NR-MIX, SUSTAINABILITY PARTNER IN JAPAN

Japan is one of the countries where Re-Con Zero EVO is most successful, thanks to the commitment of NR-MIX (Nagaoka Ready-Mixed Company), Mapei exclusive distributor of RE-CON ZERO EVO for Japan. NR-MIX is a family company, established in 1967, and 2017 is the 50th anniversary of its foundation. The current CEO, Mitsuya Miyamoto, 39 years old with a Master Degree in Political Economy at Meiji University of Tokyo, strongly believes in innovation and circular economy. For these reasons, he considers RE-CON Zero EVO as the keystone to improve the sustainability of concrete in Japan.

With his technical team, he developed an innovative concrete, ECON®, based on 100% aggregates produced from returned concrete admixed with RE-CON ZERO EVO. This new concrete is now produced at the new batching plant in Nagaoka, in the Shizuoka Prefecture, in Central Japan. Thanks to the excellent performance and durability and the low environmental impact, ECON® is now widely used as non-structural concrete for slabs, foundations and parking lots all over Japan.

Mitsuya Miyamoto is also the President of GNN, an association of more than 100 Japanese ready-mix concrete companies, many of them using RE-CON ZERO EVO to recover returned concrete. He is also very active in introducing, through GNN, innovative technologies and materials in the Japanese concrete industry, assisted by his International Business Manager Alberto Ferrari.

TESTING GOES ON

Mapei and NR-MIX, in cooperation with Shiraishi Kensetsu Ready-Mix Company, based in Okayama Prefecture, in 2015 developed RE-CON ZERO SPRAY, a special liquid additive which is sprayed inside the drum of the mixer and eliminates the need of washing the truck mixers after the delivery of concrete. RE-CON ZERO SPRAY allows to save large volume of washing water and contributes to reduce wastewater and pollution in the ready-mix concrete plants.

Recently, Mapei and NR-MIX, in cooperation with the Japanese Concrete Pumping Association and Kawabata Kogyo, a Japanese manufactuter of pump machines, have developed RE-CON ZERO PUMP, an unique product which allows to recover residual concrete from the tanks of the concrete pumping trucks. The first full container of Re-Con Zero PUMP will be shipped soon to Japan from the Mapei plant in Robbiano di Mediglia (Northern Italy).

Japan is one of the most advanced industrial countries, leaning forward with innovative spirit for creating new sustainable products and developing new sustainable technologies. Mapei and NR-MIX play an important role in this process, contributing with the Re-Con Zero product line to make the Japanese concrete industry more and more sustainable.

Giorgio Ferrari. Research & Development Laboratories, Mapei SpA

Find out more about Mapei solutions for the concrete industry at: https://www.mapei.com/cis/en/home-page