Interviewee

José Maria Vaquero

Corporate Product Line Manager, Precast concrete, Mapei Group

The precast concrete sector is experiencing dynamic growth, fuelled by increasing demands for sustainability, production efficiency, and material innovation. In this interview, José Maria Vaquero — Corporate Product Line Manager for Precast Concrete at Mapei Group — shares how Mapei is actively supporting manufacturers with tailored technical expertise and high-performance solutions. Mapei offers a 360° approach that enhances durability, optimizes production processes, and fosters sustainability

The precast concrete industry is growing rapidly. What are the main trends shaping this sector today?

The global precast concrete market is expanding at an impressive pace. In 2024, it reached 142.1 billion US dollars, and forecasts are highly encouraging: it’s expected to grow to 150.2 billion USD in 2025, and reach approximately 247.5 billion USD by 2035, with a compound annual growth rate of 5.7%1. The industry is particularly well established in regions like Europe and the USA, where over 160,000 employees work in more than 8,000 facilities across Europe2, and 120,000 workers are employed across 2,700 plants in the USA3.

Additionally, a recent McKinsey report highlights a broader trend: while global construction activity continues to rise, production efficiency is not keeping pace4. This offer a big chance to concrete industry provided that precast concrete manufacturers are helped out with their need for faster, more efficient construction processes, along with high-performance and durable products that meet increasingly demanding sustainability requirements.

What are the main challenges facing precast concrete manufacturers today?

One of the most pressing challenges is the growing demand for sustainable construction practices and materials. The precast concrete industry is increasingly expected to reduce its environmental impact, especially given its perception as a high-emission sector. Manufacturers are committed to lowering their carbon footprint but must also maintain high standards of quality and performance.

Another key issue is the changing availability of raw materials. Due to intensified construction activity in recent years, precast concrete producers are often required to work with challenging aggregates like manufactured sand, recycled concrete aggregates or clay bearing sands: materials that are more sustainable but also more demanding in terms of mix design. Ensuring early strength development and optimal rheology under these conditions is a technical challenge.

The shortage of skilled labour in the construction industry adds further pressure. This makes precast production increasingly attractive, as it allows for greater automation, reduced labor risks, and higher accuracy. However, manufacturers still need to ensure fast production cycles, cost control, and long-term durability of their products.

Mapei is actively supporting precast manufacturers in overcoming these challenges. Our solutions help make production processes more efficient and reliable, while ensuring high-quality precast products. From logistics to labour optimization, from reduced need for maintenance to increased sustainability, Mapei technologies deliver tangible benefits across the entire value chain.

Precast concrete producers are often required to work with challenging aggregates that are more sustainable but also more demanding in terms of concrete mix design. Mapei solutions help them meet this challenge while keeping high quality standards.

How is Mapei responding to the evolving needs of precast manufacturers?

Mapei is fully committed to supporting this sector. We’ve established a dedicated team focused exclusively on precast concrete, ensuring tailored technical support. From an operational standpoint, we’re expanding our production capacity by investing in new plants worldwide to guarantee fast and reliable supply.

Our R&D laboratories are developing cutting-edge solutions specifically designed for precast concrete applications. These include advanced admixtures like those of the Mapecube range, which allow manufacturers to reduce cement dosage while improving mechanical performance and sustainability.

Furthermore, with 26 product lines, Mapei provides a comprehensive portfolio that goes beyond concrete admixtures: anchoring grouts, joint sealants, waterproofing membranes, repair mortars, protective coatings, and much more. This integrated approach allows us to support precast manufacturers across the entire production cycle: from mix design to cast, installation and long-term durability. With products and people: Mapei offers a continuous, reliable and advanced service of technical support during all the phases of works.

Mapei has recently unveiled a new logo to represent its Precast Concrete Line, underscoring the company’s commitment to supporting professionals in this sector through dedicated products, expert teams, and specialized know-how.

How can Mapei’s solutions help the precast concrete industry become more sustainable?

At Mapei, we approach sustainability from two complementary angles. On one hand, we offer technologies that reduce the environmental impact of concrete production; on the other, we ensure long-term durability of precast elements.

From a materials perspective, Mapei provides a wide range of solutions to support sustainable mix design and production:

- The RE-CON AGG admixtures enable the use of challenging aggregates like manufactured sand, recycled concrete aggregates or clay bearing sands. The absorption inhibiting properties of these admixtures enable higher dosages of these materials to be used as raw materials without leading to higher demands of water and cement, reducing CO2 emissions and controlling costs.

- The CUBE System (Dynamon Cube and Mapecube admixtures) allows producers to use low-clinker cements in concrete mixes, reducing carbon emissions while maintaining high performance and ensuring durability.

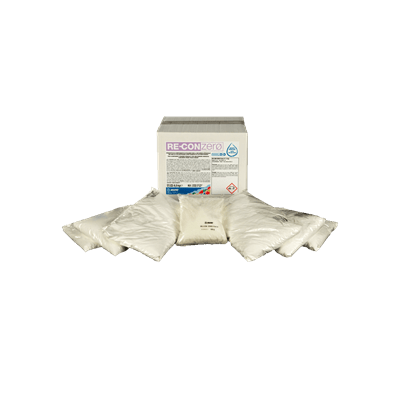

- Re-Con Zero EVO technology makes it possible to reuse surplus concrete, minimizing waste and disposal needs. The combined effects of Re-Con Zero EVO and Re-Con AGG enables a much more circular material flow, saving both transportation costs and landfill fees.

- Dynamon NRG admixtures help reduce water consumption in concrete mixes while the Dynamon Cube 8000 range promotes early strength development, even with low-clinker cement types.

- The Mapefibre range of fibers reduces the need for steel reinforcement, lowering CO₂ emissions and enhancing durability.

- Mapei also offers a unique service: the calculation of the environmental impact of our customers’ concrete mixes by using the LCA (Life Cycle Analysis) and the chance to publish EPDs for concrete mixes.

On the other hand, by extending the service life of precast components, Mapei products contribute to significantly reduce the need for maintenance and reconstruction, lowering CO₂ emissions over the full lifecycle of the structure. We believe that “durability is sustainability squared”: the most sustainable choice is to enhance existing structures, reducing the environmental impact of built works throughout their entire life cycle.

Mapei's wide range of solutions for the precast concrete industry contributes to extend the service life of precast elements, enhancing durability and reducing the need for maintenance and reconstruction.

In which way can Mapei’s solutions help precast concrete producers improve production efficiency?

Mapei offers a wide range of technologies that help precast manufacturers streamline production, reduce energy consumption, and optimize resources.

First, Mapei high-performance water reducers, such as those belonging to the Dynamon Cube 8000 range, improve rheology and enable very rapid early strength development, allowing for faster demoulding and shorter production cycles.

Second, admixtures like Mapecube 1 are designed to maximize initial strength without affecting long-term performance of concrete mixes. This can lead to a significant reduction of curing times and a reduction or even elimination of steam curing, resulting in lower energy costs, faster turnaround and reduced emissions of CO2.

Third, by incorporating Mapefibre synthetic fibers into concrete mixes, producers can reduce or replace steel reinforcement, which not only lowers labour costs and installation time, but also improves safety and accuracy during casting.

Together, these solutions contribute to a more efficient, cost-effective, and sustainable production process, helping precast manufacturers stay competitive in a fast-evolving market.

Mapei helps precast concrete manufacturers meet the challenges of this sector with effective tools, technologies and materials that can make the whole production process more efficient, faster and more sustainable.