Research & Development

/

4/5/2024

Speed tests in the Lab

A good understanding of technical and mineralogical principles is crucial for the development of high-quality rapid products

In today's building industry, reducing execution times is crucial not only for new constructions but also for restoration and refurbishment projects. Cementitious formulations play a significant role in achieving rapid strength and resistance through hydration processes. Accelerating admixtures and mixed binder systems are utilized to shorten setting times from several hours to just minutes.

Innovations in cementitious formulations for rapid construction and restoration

Reducing execution times is undoubtedly one of the characteristics of today’s building industry and regards not only new constructions, but also, and above all, restoration and refurbishment work, where we need to guarantee that environments may be quickly put back into service.

We are talking about cementitious formulations, such as those used for tile adhesives, grouts and self-levelling products in which the development of strength and resistance is due to hydration of the cement when a powdered product is mixed with water: it is on this chemical process that we need to focus. This may be achieved by adding an accelerating admixture or, to be more effective, using mixed binder systems that produce much faster reactions than those obtained with common Portland cement, to such an extent that you can go from setting times of several hours – typical in normal systems – to just tens of minutes, a characteristic of rapid systems.

Controlling and accelerating setting times is normally achieved by using a mixture of Portland cement, calcium sulphate and alumina cement

Understanding the technical and mineralogical principles of rapid systems is crucial for the development of high-quality products for which the main problems are maintaining workability against rapid-setting times, controlling the development of strength and resistance at different temperatures and controlling the aging of products which are highly sensitive due to their high reactivity. What is more, researchers need to understand the complex interactions that arise with set-retarding admixtures or with admixtures used to improve the development of mechanical properties.

A very special role is played by lithium carbonate which considerably improves strength and resistance at low temperatures, but over the last few years its procurement has become a battle because of its consumption for batteries for electric vehicles.

Controlling and accelerating setting times is normally achieved by using a mixture of Portland cement, calcium sulphate and alumina cement. Calcium sulphate and alumina cement may also be fed into the formula together in the form of aluminium sulphate cement.

Cementitious formulas

Rapid cementitious formulas cover a wide range of applications: apart from the self-levelling mortars, tile adhesives and grouts mentioned previously, there are also rapid-setting repair mortars and waterproofing products.

These products may meet a variety of needs: putting environments back into service, quick cleaning of joints, providing the possibility of applying a second layer of product where necessary, a quick drop in moisture content (a requisite when installing floor coverings), making surfaces more resistant to abrasion and ensuring better dimensional stability due to lower shrinkage rates (crucial for those cases in which the product could crack or detach).

In the case of cementitious grouts, more than twenty years ago Mapei developed new technology that does not require the use of Portland cement and that does not generate calcium hydroxide crystals during the hydration phase, which can than lead to the appearance of efflorescence on the surface: in so doing, it guarantees maximum colour stability.

ULTRACOLOR PLUS grout is based on this technology, which to this day is an unrivalled product and is available in a range of 40 colours, whose stability over time is guaranteed thanks to the chemistry it develops.

Rapid cementitious formulas cover a wide range of applications: self-levelling compounds, tile adhesives, grouts, repair mortars, and waterproofing products

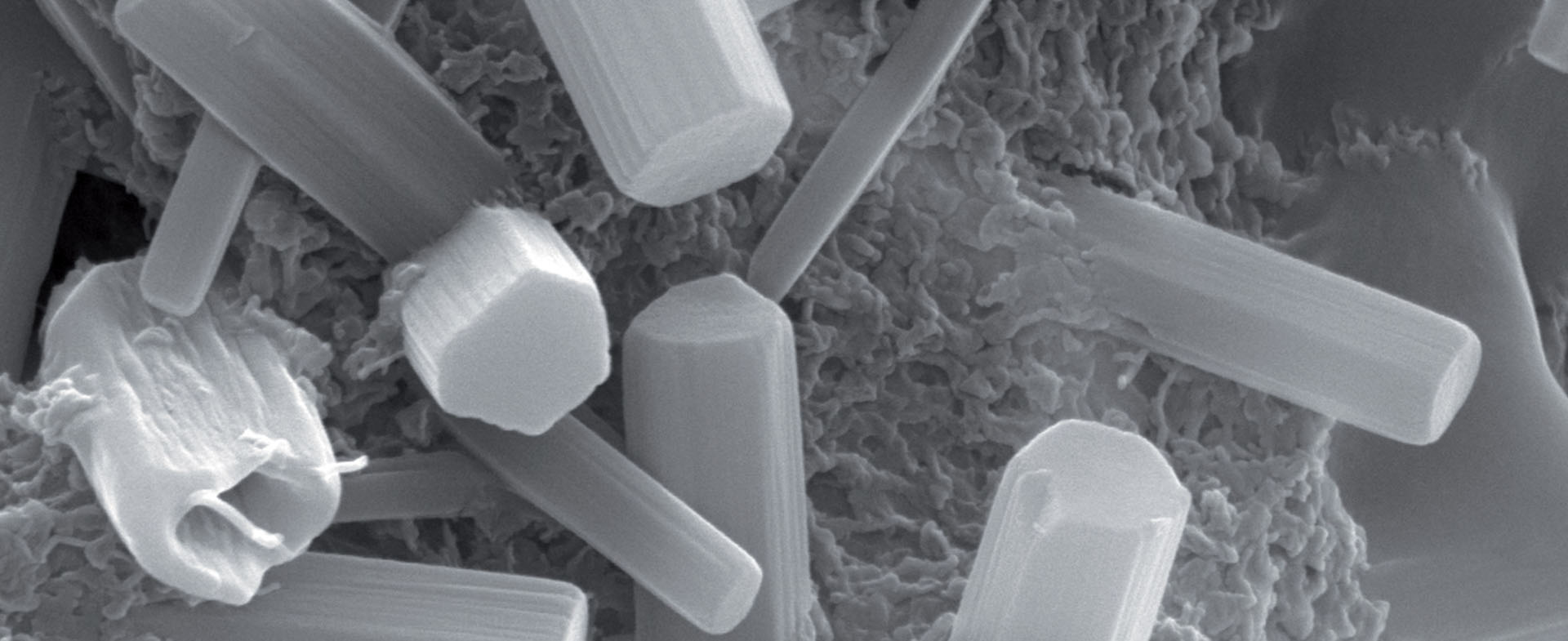

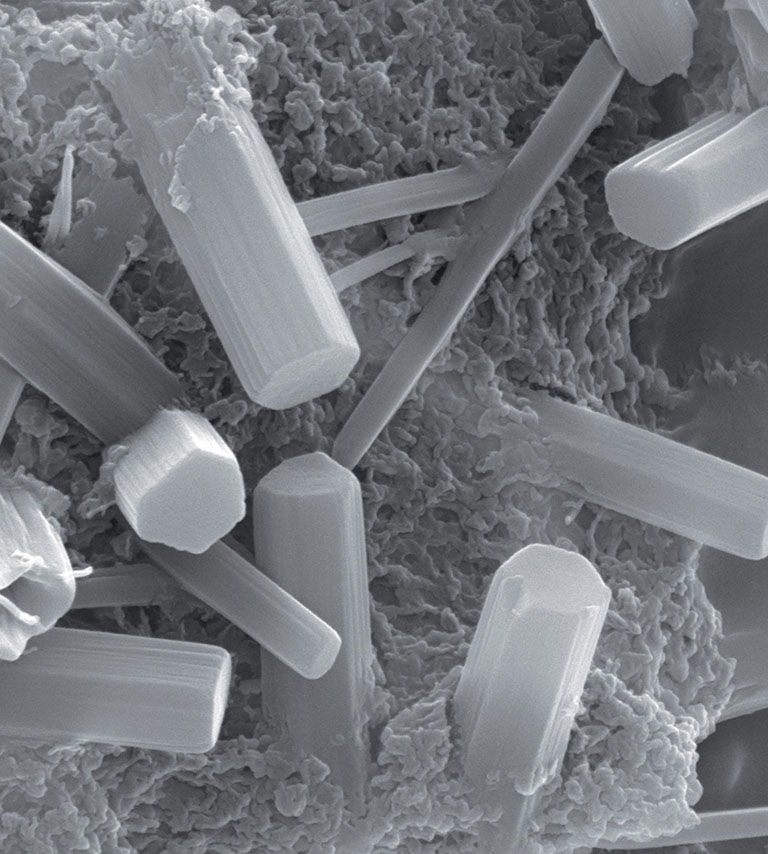

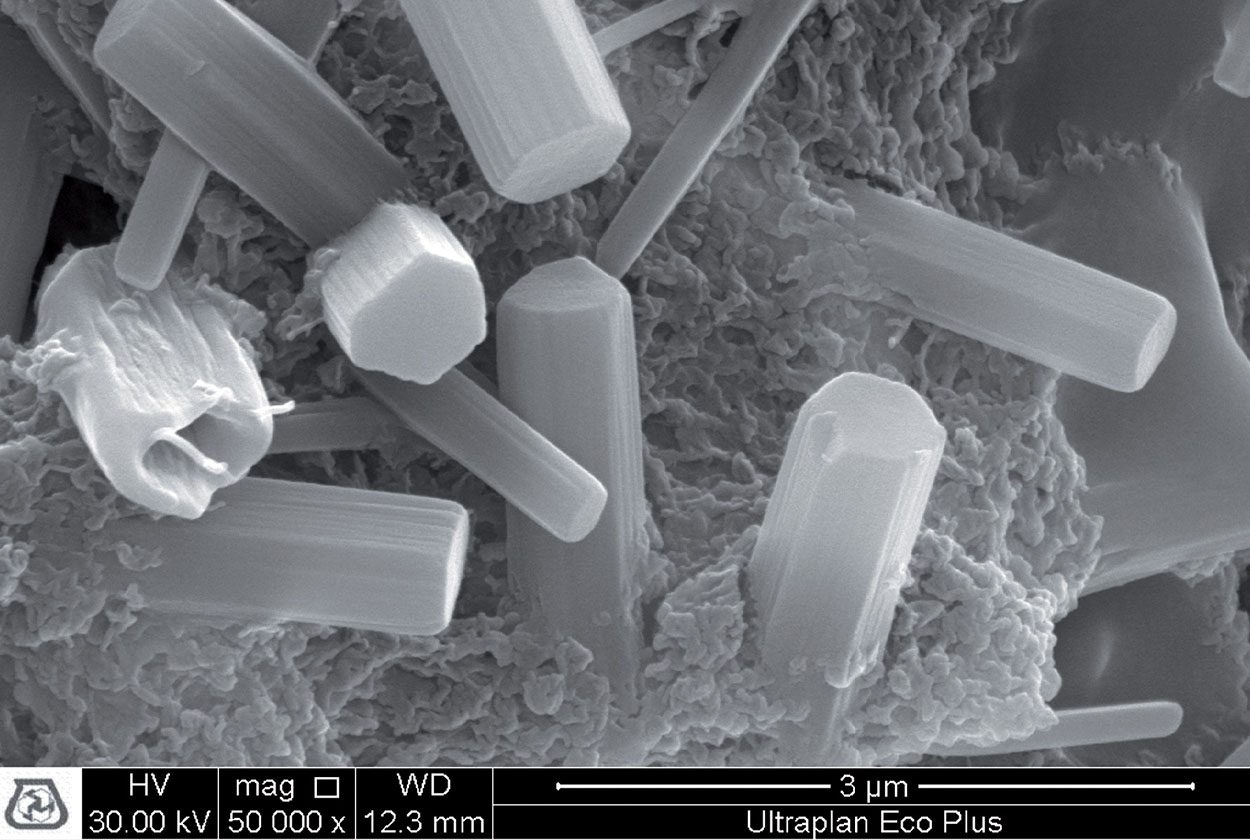

Electronic microscope image of ettringite crystals, the chemical species that forms in Mapei binders based on alumina cements. Their features are exploited to obtain rapid products.

Chemistry is the base for rapid products

The chemical element that forms mainly in mixed binder systems on which fast products are based is ettringite, which captures 32 water molecules. In fact, 47% of the weight of ettringite is given by the weight of the water captured, which is 50% higher than the amount captured during the hydration process of Portland cement.

This “water crystallisation” process is very important when installing natural stone, which is often highly sensitive to moisture and easily stained, and prevents unsightly effects appearing in the stone, a phenomenon by no means rare if the wrong product is used. Adhesives developed specifically for installing natural stone sensitive to water, such as GRANIRAPID and ELASTORAPID, exploit the chemical process described above to guarantee a surface that is immune to the problem of staining. From a chemistry perspective ettringite is an aluminate trisulphate of hydrated calcium. Ettringite crystals have a typical needle-like structure which is easy to identify with an electron microscope as one can see in the photo above.

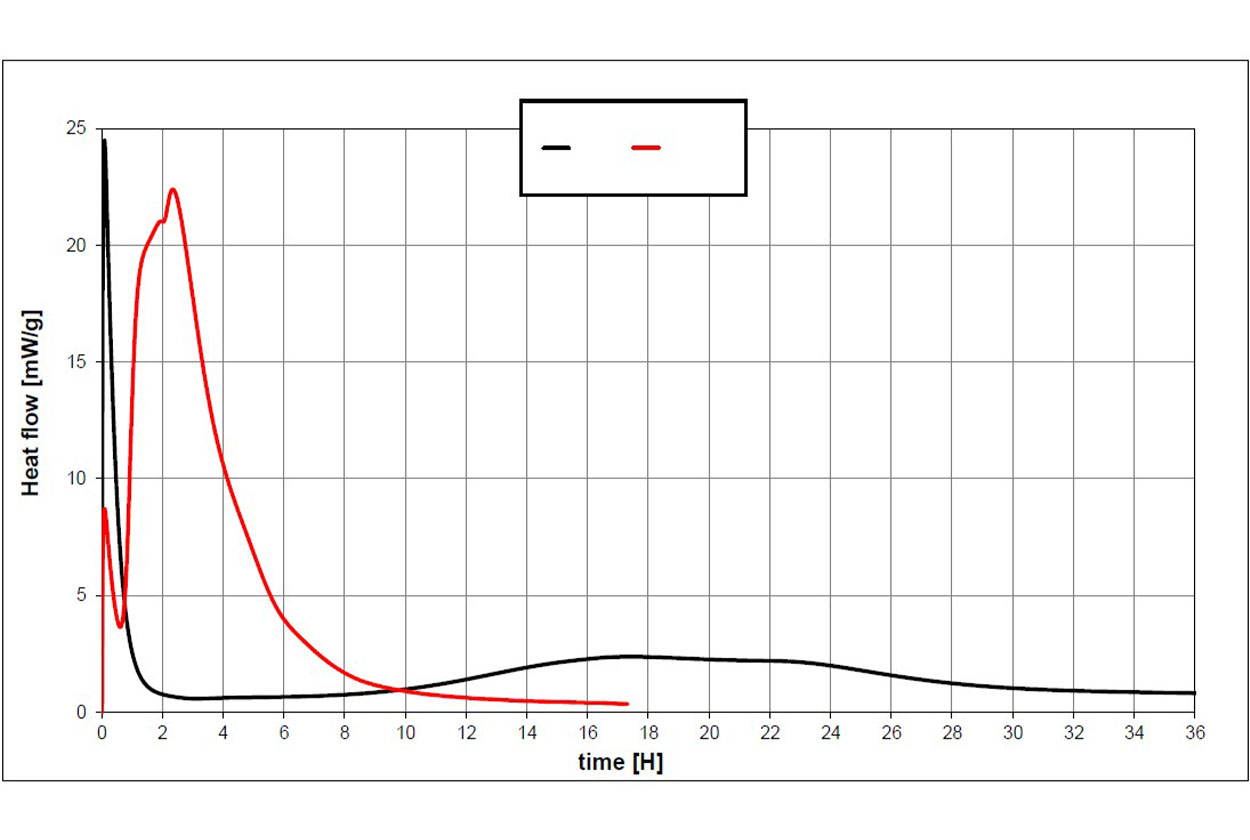

Mapei Research & Development laboratories also use a technique by which it is possible to appreciate the various kinetics of the hydration process in rapid products compared with that of normal-setting products based on Portland cement only. This is called “isothermal calorimetry”, in which a thermostatic bath is held at a constant and controlled temperature and small samples of products are inserted in the bath to measure the amount of heat generated by the hydration reaction over time. Graph no. 1 illustrates a comparison between the calorimetric profile of a rapid adhesive and a normal-setting adhesive, where we can observe that the first one has a far more intense and calorimetric curve than the second one.

This rapid characteristic is also included in European standards which describe adhesives and grouts for tiles (EN 12004 and EN 13888, respectively). In both standards rapid products are identified by the letter F (Fast), which requires their adhesion and mechanical properties to be measured after 6 hours: this is the point that specifies their minimum requirements, rather than the widely adopted 28 days for normal-setting products.

GRAPH 1. Comparison between the calorimetric profile of a rapid adhesive (C2F) and a normal-setting (C2) adhesive: the rapid adhesive has a far more intense and rapid calorimetric curve than the normal-setting one.

Self-levelling mortars

Another important sector where rapid-setting binder technology is employed is for self-levelling mortars, the scope in this case being to improve the base material to be covered (screed or concrete) and guarantee continuity and uniformity throughout its entire volume. Self-levelling products may be covered to create the final floor using a suitable adhesive (for ceramic tiles, resilient materials or wood) or remain exposed and protected, in certain cases, by a coat of resin. Since these mortars are not covered and protected during the hardening phase there is a risk – especially if applied when the surrounding temperature is high or in draughty surroundings – that the surface dries too quickly, the effect of which is to reduce surface hardness. Another problem is caused by excessive absorption of the substrate – when not primed sufficiently – which may lead to problems in the surface finish due to hydration water not being readily available for the hydration process, which then becomes irregular.

In both cases the problems may be overcome by formulating binder systems that increase the formation of ettringite, which has a high capacity to bond with water. This approach, however, may only be adopted for self-levelling products applied in internal surroundings because ettringite has a limited level of stability if used outdoors, particularly under the action of water and moisture.

With self-levelling mortars from the ULTRAPLAN line, the rapid development of mechanical properties and the rapid drying of the product are exploited to enable them to be covered after just a few days, or even after just a few hours in the case of ultra-rapid products. What is more, the mix of components that make up the binder phase may be controlled as required in order to minimise any movements in the product (which take place due to the effect of hydration reactions) to prevent detachment and cracks.

Mapei is integrated upstream with the above-mentioned technologies thanks to Górka, a Polish manufacturer of alumina cement, which joined the Mapei Group in 2000. Over the years, this extraordinary synergy has enabled Mapei products to be constantly cutting-edge in the face of the progress made in construction technology.