Mayoral logistics hub

A former industrial complex reconverted while maintaining the imposing 200 m structure intact.

A former industrial complex reconverted while maintaining the imposing 200 m structure intact.

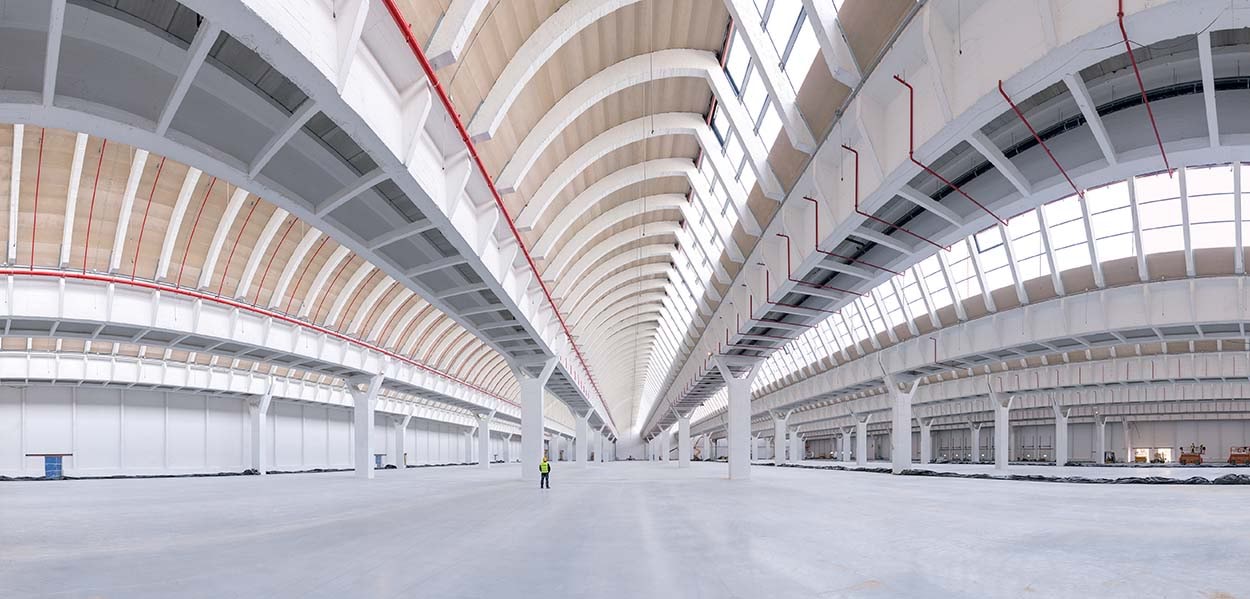

The industrial cathedral of Malaga

One of the nominees in one of the most recent editions of the Mies van der Rohe European Architecture Award was the renovation work on the Intelhorce factory designed by Manuel María Valdés and Ramón Vázquez Molezún between 1958 and 1963. The construction of an industrial complex in this area was completed thanks to a decision taken by the Spanish government to alleviate the difficult economic situation the Province of Málaga was going through at the time, through the creation of a state-owned company, Industrias Textiles del Guadalhorce (Intelhorce). Manuel María Valdés and Ramón Vázquez Molezún (the latter one of Spain’s most prominent architects in the post-war era) designed the construction of a large-scale industrial complex which, apart from the production buildings, also featured office space and areas for the workers’ activities and tools.

The building used for finishing operations, also known as “the industrial cathedral of Málaga” or “the ship”, is now the last remaining example of Málaga’s manufacturing traditions of the 20th century and is listed in the Spanish DOCOMOMO’s (Committee for Documentation and Conservation of Buildings, Sites and Neighbourhoods of the Modern Movement) Register for the conservation of urban buildings from the Modernist era. It is also in the AndalucÍa Register of Listed Buildings and is under the protection of the Special Intelhorce Plan approved by Málaga City Council in 2011.

Left to its own devices since ceasing manufacturing activities in 2004, the building was purchased by Mayoral in 2013 with the intent of transforming it into the company’s new logistics hub. The new owners decided to leave the imposing, 200 m-long quadrangular structure intact by renovating the reinforced concrete elements with more than half a century of service.

The space is divided into 9 longitudinal and 8 transversal axes with spans of 15 m and 30 m, respectively, with monumental "Y" pillars supporting the double beams for the semi-circular roof in pre-cast concrete.

One of the nominees in one of the editions of the Mies van der Rohe European Architecture Award was the renovation work on the Intelhorce factory, also known as “the industrial cathedral of Málaga” or “the ship”.

Restoration and strengthening work on the structure

Restoration and renovation work on the building started with the repair and protection of its structural elements. The designers and technicians involved in the project carried out a survey of the entire structure and identified 12 different types of repair work that needed to be carried out. Basing their considerations on the results of the survey and the mechanical properties of the existing concrete, the Technical Services team from Mapei Spain, the Spanish subsidiary of Mapei Group, was able to establish the most suitable systems and products to renovate the structure and to protect it from carbonation and exposure to chlorides.

The first step was to prepare the surfaces according to their specific area of use: the areas where only the surface needed to be refurbished were hydro-blasted and the surface was removed mechanically, while in the areas with more serious signs of deterioration larger portions of concrete were removed leaving the reinforcement rods exposed, which were then protected with MAPEFER 1K one-component, corrosion-inhibiting cementitious mortar, specific for protecting reinforcement rods.

The most consistent part of the work was the reintegration of the concrete that had been removed and the renovation of the main pillars of the façades, which were suffering from various degrees of deterioration. The vertical surfaces were repaired with MAPEGROUT EASY FLOW, an easy-flow, one-component, fibre-reinforced, shrinkage-compensated, sulphate-resistant thixotropic mortar, particularly recommended for repairing concrete structures, in this case admixed with MAPECURE SRA to reduce the final hygrometric shrinkage of the mortar and make it less prone to cracking problems.

The contact surfaces between the beams and “Y” shaped supports of the pillars also needed to be levelled off and, for this operation, it was decided to use MAPEGROUT SV T, a shrinkage-compensated mortar, that guarantees high mechanical properties and sets and hardens very quickly. In the “ribs” supporting the roof, as well as in areas of the pillars without excessive damage, the surfaces were skimmed over with PLANITOP SMOOTH & REPAIR, a fibre-reinforced, rapid-setting, shrinkage-compensated, class R2 thixotropic cementitious mortar, which may be applied in layers 3 to 40 mm thick.

Once all the renovation work had been completed, the surfaces were protected against carbonation by applying a coat of ELASTOCOLOR PAINT, a protective, crack-resistant, elastomeric paint which, when dry, forms a flexible coating impermeable to water and aggressive agents present in the atmosphere (CO2–SO2) but permeable to the passage of vapour. This product also guarantees excellent resistance to ageing, freezing weather conditions and de-icing salts, and the photo-chemical film which forms on the surface makes it very difficult for dirt to remain attached.

Shrinkage-compensated concrete floors