Marco Squinzi: "On the road to sustainability"

Marco Squinzi, CEO of Mapei: our contribution to low carbon footprint concrete.

Marco Squinzi, CEO of Mapei: our contribution to low carbon footprint concrete.

Why is it so important to focus attention on sustainability in the production of concrete?

The concrete industry is looking into every avenue possible to reduce the impact it has on the environment, in terms of both carbon footprint and the concept of circularity, focusing on construction and demolition waste and optimising the consumption of virgin raw materials. Concrete is such an important construction material that we have no other choice than to focus on this issue, both in our Research & Development laboratories and by collaborating with our clients. This approach is part of Mapei’s DNA because we have always developed products and solutions by investing in Research. In fact, we are absolutely convinced that you cannot achieve sustainable growth without Research & Development: for us the road to sustainability is, first and foremost, through innovation. In Mapei we dedicate more than 70% of R&D work to product optimisation to make them more and more durable, of the highest quality and to have less impact on the environment. The 32 R&D laboratories of the Group focus on solutions for the recovery and recycling of materials, the aim being to contain the consumption of virgin raw materials entering our facilities and to partially replace raw materials with a high impact on the environment, in terms of both formulation and packaging, to promote a circular economy.

What activities are being carried out to reduce the carbon footprint of concrete?

Our CUBE System and MAPEFAST ULTRA admixture (that makes use of Secondary Nucleation technology and was used for the San Giorgio Bridge in Genoa) offers the most complete range of strength enhancers on the market. We have worked on every type of cement with low CO2 emissions and we are in a position to propose solutions for every type of cementitious material. The system offers a platform that helps our clients produce concrete with stable and predictable characteristics.

In what way can the products offered by Mapei help overcome the problem of the scarcity of natural raw materials?

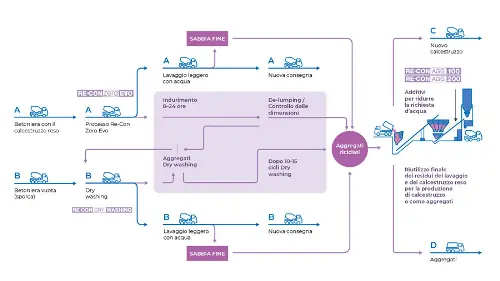

Part of our offer for the concrete industry focuses on increasing the possibility of using recycled and recovered materials and recycling returned concrete, that is, concrete excluded from construction operations. Some of our solutions – I am thinking about the RE-CON LINE here – help limit the production of waste and the consumption of natural resources. In fact, the availability of sand and aggregates is diminishing in many areas due to the increase in their extraction to meet the growing demand of the world of construction and even water is becoming a critical resource and we must avoid wasting or polluting it. RE-CON ZERO technology, which is used to transform returned concrete into new, reusable aggregates without producing any waste, earned us the 2019 Circular Economy Award: a great example of how the contribution of the construction sector is fundamental in the implementation of the principles of a circular economy. The RE-CON DRY WASHING technology, which is unique in the world, allows the dry washing of the concrete mixing trucks with almost no water.

On a global level, is there a new, growing awareness in construction work as regards sustainability?

The main challenges today are played out at various levels. The global application of voluntary eco-sustainable building protocols such as LEED and BREEAM, for example, is playing a fundamental role in ecological transition, a stimulus for the use of certified products in the construction industry. And, the inclusion of Minimum Environmental Criteria (CAM) in local authorities’ purchasing process in Italy has undoubtedly acted as a stimulus to come up with a different approach to design and construction, taking into consideration the life cycle of an entire building. And lastly, in the infrastructure sector, the Envision protocol is also becoming more widely adopted in Europe. This is the first rating system, developed with the contribution of the University of Harvard, for designing and building sustainable infrastructure.

What role does the digitalisation of processes play?

Mapei has a long history of collaborating with universities: what results have you achieved in this sector?

Mapei collaborates with the scientific community to share ideas and know-how. In 2021 we developed a cutting-edge accelerating admixture for concrete in collaboration with Centro CIRCe (Interdepartmental Research Centre for the Study of Cementitious Materials and Hydraulic Binders) at the Faculty of Geosciences of the University of Padua (Italy). And it is precisely to contribute to the eco-sustainability of concrete structures that we are participating in a pilot project at the University of Brescia, with financial backing also from the EU as part of the PNRR (National Recovery and Resilience Plan) initiative, for the development of a concrete mix with less impact on the environment and high mechanical properties, which will then be used in the construction of the Milan Innovation District (MIND).

Find out more about Mapei solutions for the concrete industry at: https://www.mapei.com/cis/en/home-page