MapePave offers durable, high-performance paving solutions designed for professionals and DIYers alike. Whether you're a tiler, landscaper, or homeowner, our easy-to-apply products ensure a seamless, weather-resistant finish for patios, pathways, and outdoor spaces. From brush-in grouts to specialist adhesives, MapePave delivers lasting results with minimal effort.

MapePave Range is intended to make it easier to lay natural and engineered stone pavers all year.

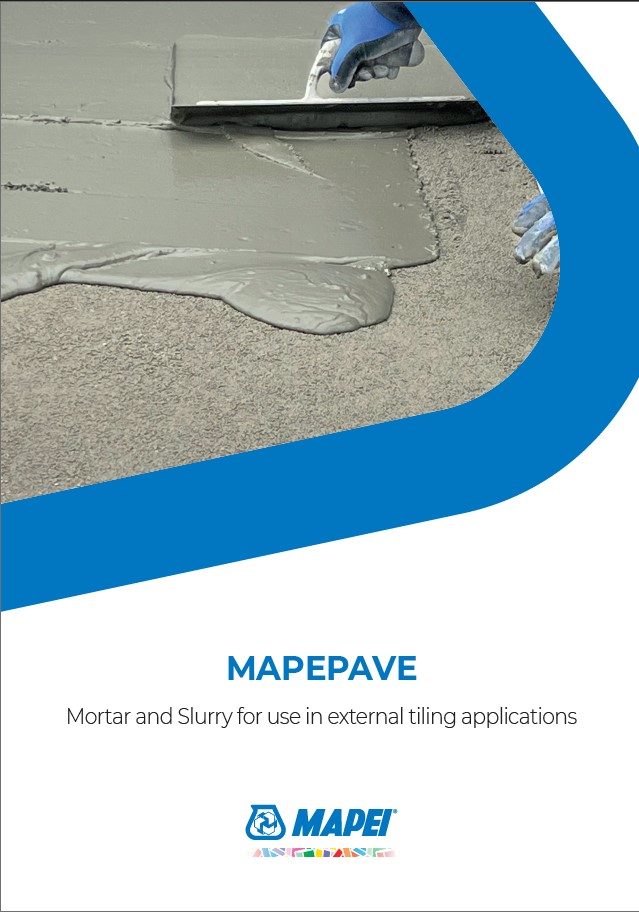

It includes a ready-to-use mortar system (MapePave Mortar and MapePave Slurry) that enables normal setting and regulated shrinkage for fast-drying bedding and installation of 20mm porcelain and natural stone.

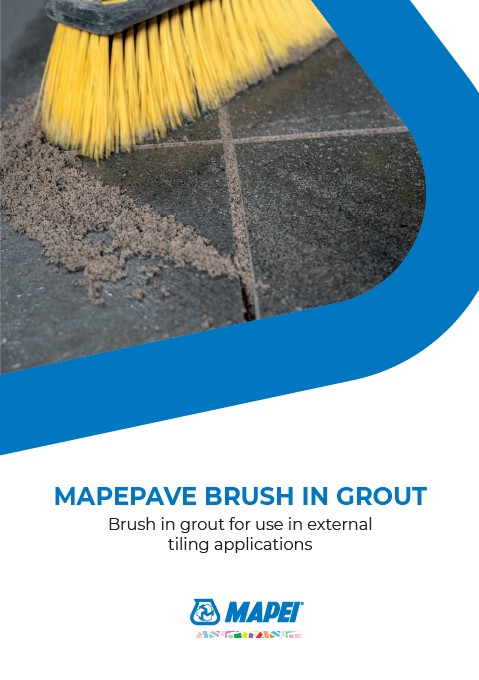

MapePave Brush in Grout a single component ready-to-use polybutadiene-based drainage mortar for grouting paved floors with joints at least 5 mm wide.

Brochures, manuals, guides

Brochures, manuals, guidesA Mapei concrete system is being used to complete a project at HS2’s Delta Junction project near Birmingham. Works being carried out by Balfour Beatty VINCI include grouting of rail bearings on top of viaduct concrete piers and application of protective concrete. All Mapei products are being supplied by Bluebay Building Products.

Delta Junction comprises 13 viaducts and will enable high speed trains to travel between London and Birmingham, Birmingham and Manchester, and direct between London and Manchester without stopping at Birmingham. Upon completion, more than 8.7 miles of track will run through the network, crossing over the M6, M6 toll and M42, as well as roads, rivers, and railway lines. The triangular junction was designed by landscape architects and engineers from the Mott MacDonald SYSTRA Design Joint Venture (DJV), working closely with architects WW+P. It will include connected and accessible areas, extensive tree planting, and new wildlife habitats around viaducts.

The project started in April 2024 and is ongoing. Mapei is working closely with the project team throughout the works, providing technical support and a specification which includes precision grout, curing admixture, and flexible cementitious mortar from Mapei’s Zero Line.

To grout rail bearings, Mapefill 110 pre-blended precision grout is being applied to the underside of steel bearing plates, on top of the viaduct’s concrete piers. Mapefill 110 comprises high-strength cement, graded aggregates, and special admixtures developed for highways, bridges, and viaducts subject to high dynamic loads. Mapecure SRA – a curing admixture that reduces hydraulic shrinkage and the formation of micro-cracks – is then applied as an internal curing material.

Colour-matched, flexible cementitious mortar, Mapelastic Guard Zero is also applied to increase concrete cover and provide a protective layer over steels, following movement of shuttering and reinforcement during the concrete pour. Mapelastic Guard Zero is included within Mapei’s Zero Line, with CO2 offset in the entire lifecycle.

If you would like to be kept up to date with all the developments and industry news from Mapei UK.

Click here to sign up - https://www.mapei.com/gb/en/newsletter