CO2 emissions measured throughout the life cycle of products from the Zero line in 2025 using Life Cycle Assessment (LCA) methodology, verified and certified with EPDs, have been offset through the acquisition of certified carbon credits in support of forestry protection projects. A commitment to the planet, to people and to biodiversity. For more details on how emissions are calculated and on climate mitigation projects financed through certified carbon credits, click here.

The residual CO2 emissions from the products of the new Mapei ZERO line are fully offset; a commitment to quality that enables the construction and sustainable renovation of existing buildings, with an eye toward future generations, the well-being of the planet, and those who inhabit it.

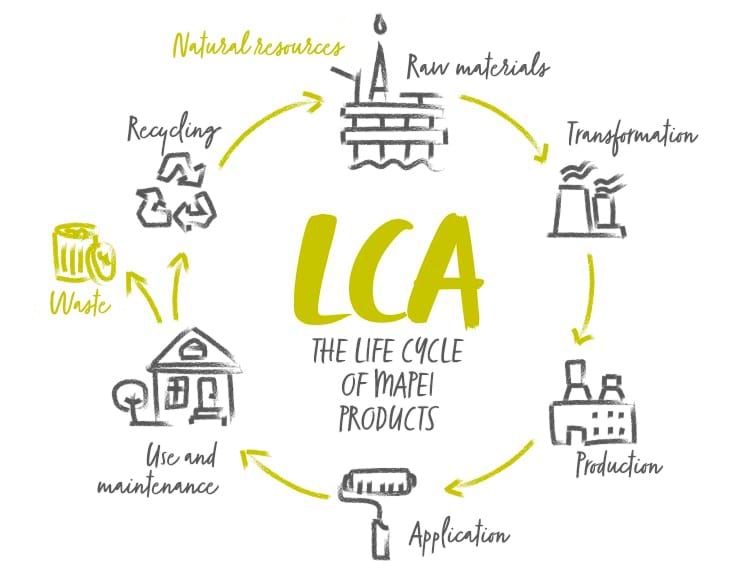

CO2 emissions from our products are expressed in kg CO2 eq/kg of product and are calculated using standardised LCA (Life Cycle Assessment) methodology. The analysis of the life cycle of a product is an evaluation of the environmental impacts the product has throughout all the various phases of its life, from cradle to grave: from extraction of the raw materials that make up the formula to their transport to the production plant, the production cycle, product packaging, waste materials, transporting the finished product to the distributor and its final disposal.

The results obtained through LCA are verified and certified by an external body with an EPD, or Environmental Product Declaration. An EPD shows the environmental impact of a product during its life cycle.

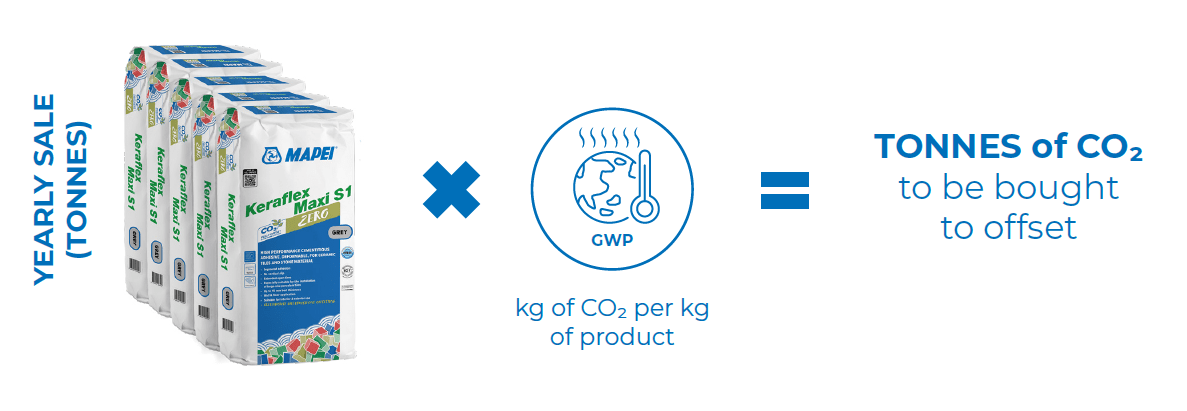

Once the amount of CO2 has been calculated and expressed in kg CO2eq/kg of product, this figure is multiplied by the amount in tonnes of product sold.

Concrete is the world’s most consumed construction material [1]. It is estimated that 3% of produced concrete gets returned and disposed of, which translates to approximately 900 million tons per year of concrete waste [2]. Disposing of returned concrete to landfill greatly impacts the environment, which, if expressed in terms of “equivalent” CO2, has an impact of 267 kg of CO2 for every cubic metre of returned concrete [3]. CO2 is the most emitted greenhouse gas on the planet [4], making it one of the most significant contributors to global warming.

WHAT IS RE-CON ZERO EVO, AND HOW DOES IT SOLVE TWO PROBLEMS WITH ONE ‘STONE’?

Re-Con Zero Evo is a two-component powder product made from a unique formula developed in the MAPEI research laboratories, which allows returned concrete to be completely and quickly recovered directly from mixer trucks turning the waste concrete into recyclable aggregate. This eliminates the need to send waste concrete to treatment plants or landfill and the requirement for any additional treatment equipment.

The aggregates formed with Re-Con Zero Evo to waste concrete can then be used to partially replace natural aggregates when mixing new concrete. Concrete will maintain similar performance when up to 5% of the amount aggregates in the concrete mix is replaced with the Re-Con Zero recycled aggregates. With assistance from MAPEI technical expertise [5] to evaluate the performance of the concrete mix, up to 50% replacement of natural aggregate can be made possible.

Re-con Zero Evo transforming linear economy to an in-demand “Circular economy” in the construction world essentially solves two problems with one ‘stone’.

1- Reduces the depletion and decline of natural resources.

2- Reduces waste and the use of landfill sites.

SUCCESS OF RE-CON ZERO EVO IN PANORAMA PARK IN IZU NAGAOKA JAPAN

Located approximately 100 kilometres south of Tokyo, the Peninsula of Izu separates the Bay of Suruga and the Bay of Sagami. Being known for its hills and features of volcanic origin covered by rich, lush vegetation, the area has become a significant tourist attraction in Japan. The region is planned to host indoor cycling events at the upcoming Olympic games.

In 2018, it was decided to extend the cable car departure station car park by approximately 1,500 m2 due to the expected increase of visitors.

Roller-Compacted Concrete (RCC) was used to construct the new extension of the car park. RCC is an ultra-dense type of concrete placed using the same equipment for asphalt road surfaces. Using RCC concrete eliminated the use of formwork or steel reinforcement during the construction of the concrete surfaces, which also helped the structure achieve high mechanical properties and durability.

Nagaoka Ready-Mixed Concrete NR-MIX company, a distributor of RE-CON ZERO EVO in Japan, was responsible for carrying out the construction car park’s extension surfaces. With Re-Con Zero Evo, an overall amount of 170 m3 of RCC was placed, with a dose of just 69 kg/m3 of cement and 2,220 kg/m3 of recycled aggregates.

The sustainable construction used approximately 380 tonnes of recycled aggregates from returned concrete, thus saving the same amount of natural aggregates that would have otherwise been used. This also made it possible to prevent disposing the same amount of returned concrete to landfill sites, saving 100,000 kg of CO2 emissions.

Mapei have the technology and knowledge on how to support your business in sustainable solutions. Contact us to find out more.

Max Fernando

Technical Engineer

Mapei Australia