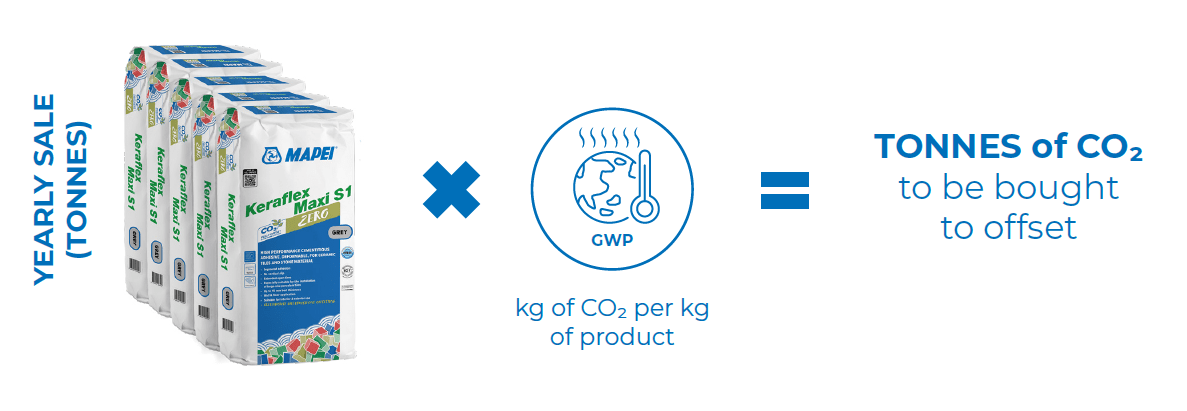

CO2 emissions measured throughout the life cycle of products from the Zero line in 2025 using Life Cycle Assessment (LCA) methodology, verified and certified with EPDs, have been offset through the acquisition of certified carbon credits in support of forestry protection projects. A commitment to the planet, to people and to biodiversity. For more details on how emissions are calculated and on climate mitigation projects financed through certified carbon credits, click here.

The residual CO2 emissions from the products of the new Mapei ZERO line are fully offset; a commitment to quality that enables the construction and sustainable renovation of existing buildings, with an eye toward future generations, the well-being of the planet, and those who inhabit it.

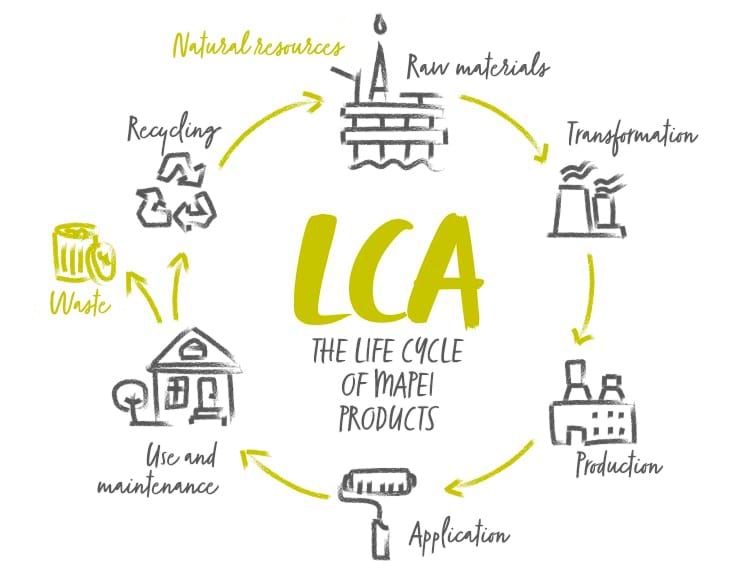

CO2 emissions from our products are expressed in kg CO2 eq/kg of product and are calculated using standardised LCA (Life Cycle Assessment) methodology. The analysis of the life cycle of a product is an evaluation of the environmental impacts the product has throughout all the various phases of its life, from cradle to grave: from extraction of the raw materials that make up the formula to their transport to the production plant, the production cycle, product packaging, waste materials, transporting the finished product to the distributor and its final disposal.

The results obtained through LCA are verified and certified by an external body with an EPD, or Environmental Product Declaration. An EPD shows the environmental impact of a product during its life cycle.

Once the amount of CO2 has been calculated and expressed in kg CO2eq/kg of product, this figure is multiplied by the amount in tonnes of product sold.

INDOOR AIR QUALITY AND VOC

Studies have shown that people are increasingly spending more time in indoor environments. Continuous lockdown measures and stay at home orders to prevent the spread of COVID-19 has increased this time significantly. Therefore, it has never been more important to ensure the indoor environment we live in is comfortable and safe for our health.

Indoor environment quality (IEQ) factors, such as air quality, temperature, and lighting impact human’s health, comfort, and productivity (1).

A key indicator of indoor air hygiene is the concentration of volatile organic compounds (VOC) in the air. VOCs are a group of chemicals that can be found in building and maintenance products such as paint, cleaning products, adhesives, carpet, and wood products. Chemicals in these products can easily evaporate into the air we breathe and adversely impact our health and overall wellbeing (2).

Studies conducted by the United States Environmental Protection Agency (EPA) show that people can be exposed to very high levels of pollutants when using products containing organic chemicals and that concentrations of these chemicals can remain at high levels in the air for a long time (3).

It is therefore important to ensure chemical products used for maintenance and building work, have undergone a VOC emission test and that the product’s VOC emission readings are under a safe threshold. For further information on VOC refer to the previously published Mapei Article ‘Innovations in Indoor Air Quality and Comfort: How to Identify low VOC Products’

VOC EMISSION TESTING METHODOLOGIES

There are several different testing methodologies that manufacturers may decide to test products for VOC emissions including GEV-EMICODE, Blue Angel, AgBB and the California Department of Public Health CDPH Standard Method.

A study conducted by Eurofins Denmark compares these testing protocols and show that GEV-EMICODE EC1 PLUS includes the strongest requirements on low VOC emissions, whilst CDPH method is much easier to fulfil (4).

Mapei Analytical central laboratory based in Milan, Italy is equipped with 12 emission chambers where products are analysed to ISO 16000 (Part 3,6 and 9) in terms of VOC emissions. This technique is used for both voluntary and mandatory schemes in Europe including GEV-EMICODE, Blue Angel, M1, Logo Sanitaire and U Mark.

Most Mapei products are certified by the GEV-EMICODE voluntary label. Thus, our customers can be confident that Mapei products are safe as they are tested under the strictest requirements for VOC emissions.

VOC EMISSION TESTING IN GREEN STAR

In Australia, Green Star is the leading rating system for sustainable buildings. This rating tool is managed by the Green Building Council of Australia (GBCA).

The latest Green Star rating tool “Green Star Buildings” offers a credit based on the project passing an onsite VOC emission test in addition to using products with low VOC content as a minimum requirement (Credit 13 - Exposure to Toxins). Green Star Buildings recommends projects to use products that have undergone a VOC emission test to mitigate the risk of failing an onsite VOC emission test.

Not only is Mapei confident that our products will not be the cause of failing an onsite VOC emissions test, but also that our products are safe to the installers as well as the end users.

VOC emissions test certificates can be found at the bottom of each product page on our website.

The Mapei Australia Technical Department is always ready and available to assist project teams with any enquiry regarding sustainability.

Max Fernando

Technical Engineer B. Eng (Hons)

Mapei Australia