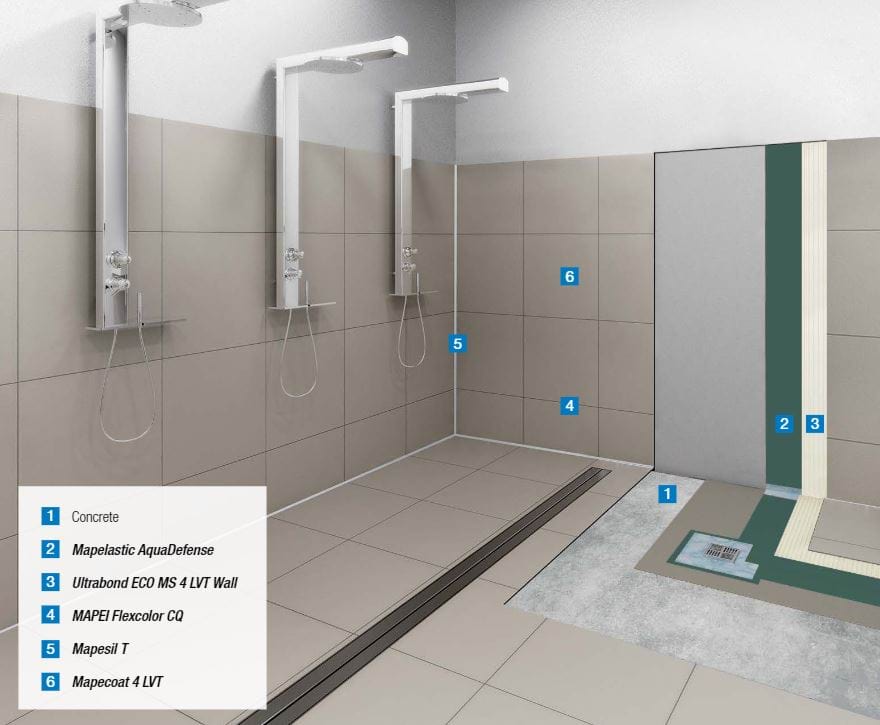

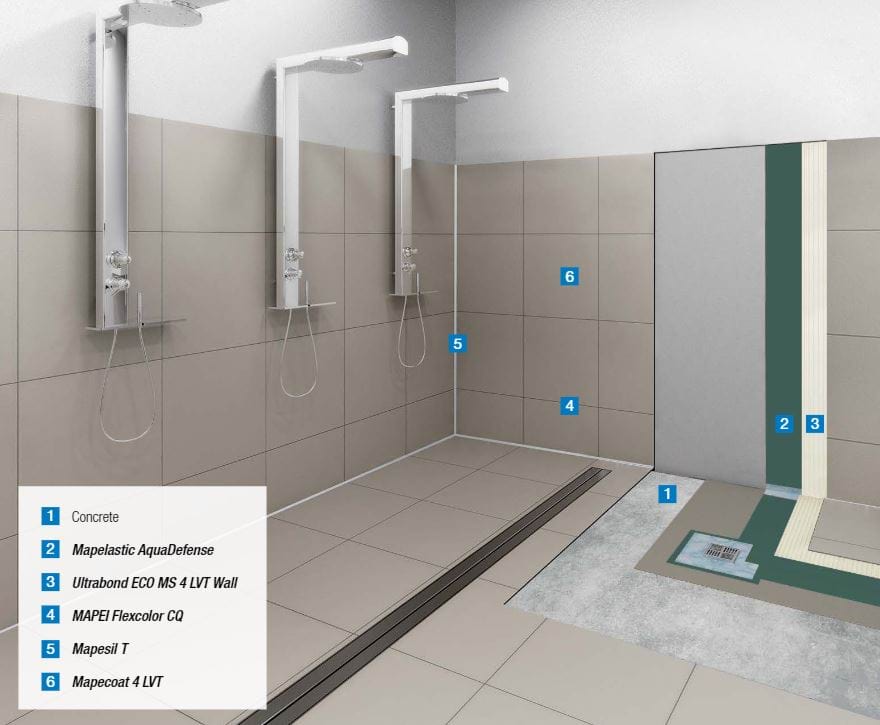

Installation steps for LVT/LVP

The installation of LVT/LVP in wet environments starts off similarly to tile projects, with the proper placement of a

waterproofing membrane over the entire surface. The surface can virtually be anything ranging from cement boards to waterproof boards to drywall.

The critical success factor is 100% compliance in the installation of the waterproofing membrane. This is no different than what you would expect for tile installations, so it is crucial to make sure to follow this step according to all written instructions on Technical Data Sheets and installation guides. There are several types of waterproofing membranes available from multipart cement-based to fabric membranes to roll-on coatings, and all will work for LVT/LVP installations. MAPEI recommends the use of

Mapelastic AquaDefense for this application primarily because it is easy to apply, dries quickly and works exceedingly well.

The next step is one that is specific for resilient material being installed: Make sure the surface is very smooth and flat. If tile were being installed, you could deal with substrate defects with the mortar bed being used. But for resilient flooring materials, you must make sure the surface is smooth and flat, otherwise those defects will telegraph through to the final finish. For this, you will need a special smoothing compound that will bond tenaciously to nonporous substrates, dry quickly and be waterproof when dry.

This is exactly what

Planiprep 4 LVT is: A one-component, premixed skimcoating compound that applies very easily, dries quickly, sands to a super smooth surface and is waterproof when dry. Next comes the installation of the LVT/LVP on the vertical surface. For this, you will need a special waterproof adhesive to apply a nonporous material (LVT/LVP) over a nonporous substrate.

Ultrabond ECO MS 4 LVT Wall fits all those requirements. As a modified-silane-based, 100%-solids adhesive designed to install LVT/LVP of all sizes in vertical applications, it has the proper thixotropy to hold these materials on the wall without slippage.

Ultrabond ECO MS 4 LVT Wall cures fairly quickly and is ready for the next installation steps in about 6 to 12 hours after installation.

Depending on the desired finished look, you may choose to use tile spacers when placing the LVT/LVP to leave an area for grouting, or you can simply butt the pieces of LVT/LVP tightly together. Grouting is not a requirement for this system and is purely an option based on personal preference. If grout lines are desired, then the only requirement is to use a resin-based grout such as

MAPEI Flexcolor CQ or

Kerapoxy CQ. The use of cement-based grouts is not recommended. For easiest installation,

MAPEI Flexcolor CQ wins the day in that it is premixed and ready to use, although it will require about 12 to 24 hours of curing time before the final step in the process. This wait time can be shortened with the use of

Kerapoxy CQ epoxy grout, which can reduce the cure time to 4 to 6 hours, but epoxy grouts are not for the faint of heart to use.

The final step – and perhaps the most important one – is the application of a sealer and non-slip coating onto the LVT/LVP. This step is accomplished with MAPEI’s

Mapecoat 4 LVT, a two-part, aliphatic, non-yellowing isocyanate-based coating that seals all the joints as well as adds much needed traction for floors. Most LVT/LVP is not designed to be used per se in wet environments and that is why the non-slip coating is so important to this process.

Mapecoat 4 LVT is simply mixed together and applied using a 1/4" (6 mm) nap roller to all surfaces.

Once

Mapecoat 4 LVT is applied and allowed to cure for 24 hours, the installation is almost ready for water exposure. For complete waterproofing protection, finishing details can be handled by using

Mapesil T in all the corners and plane changes.

In summary, MAPEI offers an innovative system of products to enable the secure installation of LVT/LVP in virtually all environments, especially in those that will be exposed to water such as tub surrounds and shower enclosures.

About the author:

|

Jeffrey B. Johnson

Jeff is the Business Manager for MAPEI’s Floor Covering Installation Systems line. Jeff brings to the industry more than 30 years’ experience in the development and marketing of floor-covering installation products. Practical experience in the construction industry and as a bench chemist gives Jeff an insightful perspective on surface preparation, moisture mitigation and floor-covering installation.

|

|