The residual CO2 emissions from the products of the new Mapei ZERO line are fully offset; a commitment to quality that enables the construction and sustainable renovation of existing buildings, with an eye toward future generations, the well-being of the planet, and those who inhabit it.

Mapei offsets the CO2 residual emissions generated by all activities involved in the production of its products through reforestation projects and biodiversity conservation.

A commitment to the planet, to people and to biodiversity. Choose sustainability for all your projects, with Mapei. Commitment to sustainable construction.

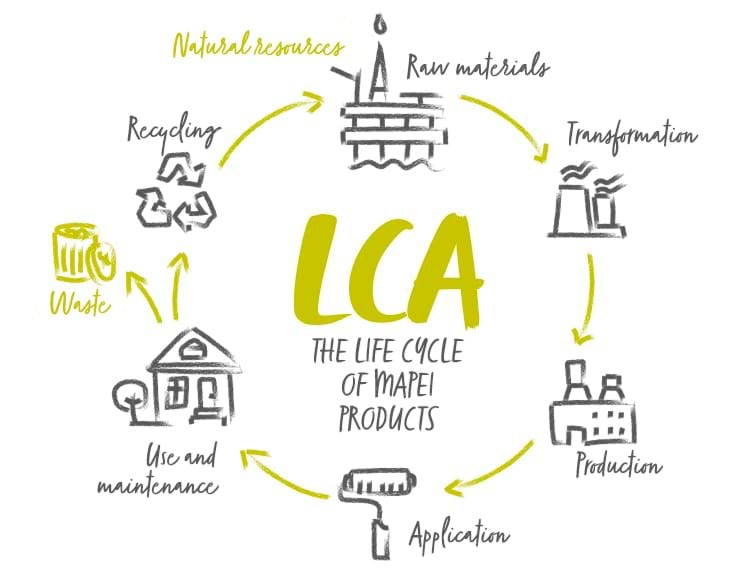

CO2 emissions from our products are expressed in kg CO2eq/kg of product and are calculated using standardised LCA (Life Cycle Assessment) methodology. The analysis of the life cycle of a product is an evaluation of the environmental impacts the product has throughout all the various phases of its life, from cradle to grave: from extraction of the raw materials that make up the formula to their transport to the production plant, the production cycle, product packaging, waste materials, transporting the finished product to the distributor and its final disposal.

The results obtained through LCA are verified and certified by an external body with an EPD, or Environmental Product Declaration. An EPD shows the environmental impact of a product during its life cycle.

Discover all the products EPDs on the Products information library.

Concrete is an essential material in construction. Its importance stems from its strength, durability, and versatility. Globally, concrete consumption amounts to billions of tons used every year (second only to water). Ordinary Portland cement (OPC) has a high carbon footprint associated with the use of clinker-rich cements; the use of alternative cements (with reduced clinker content) leads to a reduction in carbon footprint and therefore represents a valid alternative.

In this context, MAPEI has developed the CUBE system. An integrated approach that helps the concrete industry overcome challenges related to the use of low-clinker cements and variable-quality aggregates through various phases: production, transportation, and installation. The CUBE system actively assists the industry in maintaining its high standards while reducing its climate impact.

Encouraging the collection of empty paper bags, once the material has been used on-site, to take them to a recycling plant and produce recycled paper for a new production of bags for other products in a true circular economy process.

Thanks to this project, companies can deposit empty bags in dedicated areas, called Preliminary Collection Centers, at building material retailers designated for the recovery of construction and demolition waste by REC consortiums. The packaging deposited at collection centers is then sorted in specialized management and selection plants, which prepare them for processing at the paper mill, which can recover them with circularity in mind, giving them new life.

Mapei's multi-layer paper packaging, analysed according to UNI 11743 and classified according to Aticelca 501 evaluation system (Italian Technical Association for Cellulose and Paper), "recyclable with paper," with yields in terms of fibers up to 90% and up to 80%.