The use of resin-based flooring systems have become a consolidated practice in construction. Not only are they adopted in the industrial (e.g. factory, warehouse) sectors, they are also used in commercial and residential settings (e.g. offices, showrooms, retail stores, homes, etc) and even as furniture fittings (e.g. countertops).

Resin flooring solutions are extremely durable when properly installed. They are seamless, hardwearing and highly resistant to abrasion. However, issues such as bubbles and blistering (a fairly common problem) can occur and can ruin an otherwise good work.

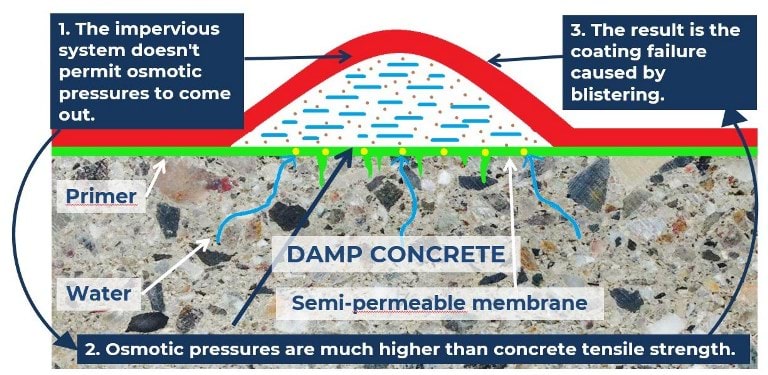

Blistering undergo osmosis, which is defined as the movement of a solvent through a semi-permeable membrane from a less concentrated solution to a more concentrated one. Osmosis only occur in the presence of three factors:

When osmosis occur, moisture is moved up from the concrete surface, through the substrate and push underneath the cured resin which results in blistering. Blistering do not occur immediately, it takes a while for this pressure to build up.

Blistering can result due to the following:

Bubbles, on the other hand, is not the result of water damage but environmental or substrate problems, particularly during the drying or curing process. Below are scenarios that can cause bubbles formation on resin flooring:

It is better to anticipate possible problems and go with the right installation before problems surface which will result in time consuming process and costly to repair. Below are some preventive measures to reduce the problem of blistering and bubbling in resin flooring:

Do moisture test on substrate

It is recommended to measure the moisture content of the substrate before any application, during curing and after it has dried (for new applications). The moisture content must be less than or equal to 4% by surface moisture content of the concrete substrate. A moisture meter can be used to conduct such testing. The test will determine the type of floor coatings suitable for the project and whether a moisture vapour barrier is required.

Select the correct floor coating material

Typically polyurethane solutions offer breathability on moist and damp substrate whereas epoxy solutions do not and will require damp proof membrane prior to installation. To find out more about the difference between epoxy and polyurethane coatings, read this post. A simpler way is to choose a water vapour permeable product or system. In this way, moisture can escape and will not be trapped underneath, thus reducing the chances of blistering.

Right application

It is important that the coating components are mixed thoroughly and evenly distributed during mixing and that it is evenly applied.

Experienced and skilled installation

Get a flooring specialist to inspect the facility beforehand to ascertain the environmental factors that may affect the new flooring. A highly skilled and trained applicator who knows what they are doing will ensure a smooth operation.

Contact Mapei Singapore Flooring Specialist Team for consultation on your flooring needs.