Projects

N° 37 - 10/18/2023

Planiseal CRI used to waterproof condominium parking garages

Planiseal CRI used to waterproof condominium parking garages

Got questions? Get answers.

MAPEI's new FAQ tool answers your most common – and uncommon – questions.

Planiseal CR1 cold-fluid-applied waterproofing receives Miami-Dade NOA approval for:

NEW! UltraCare® Grout Refresh™ Calculator

Renovate and renew – or even completely change – your grout’s color with ease and the right amount of grout colorant using this easy-to-use product calculator.

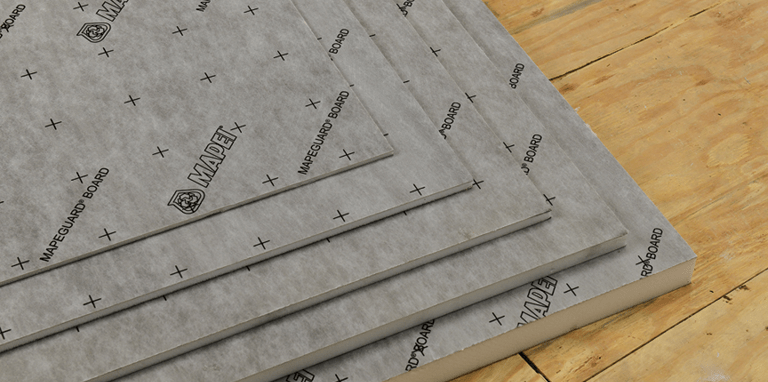

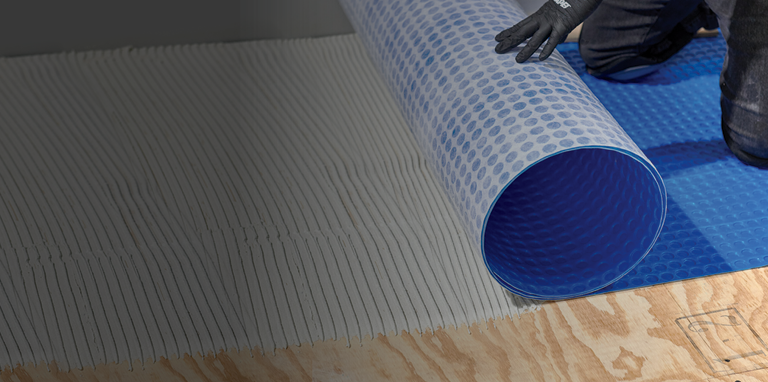

Mapeguard® UM 35

Reshaping the Industry

Uncoupling, crack-isolation and waterproofing membrane

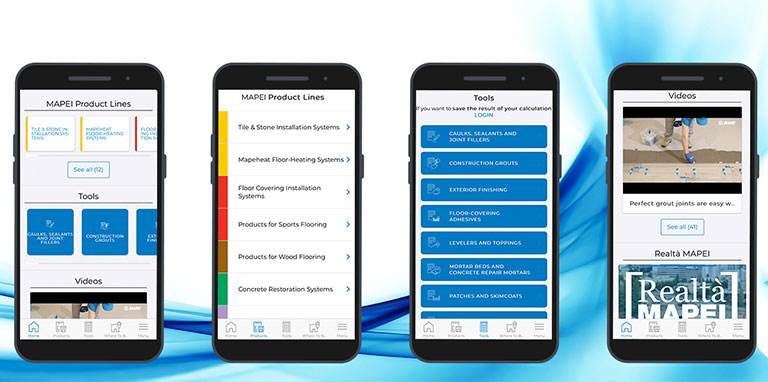

The world of MAPEI in your hands. If you have not

already downloaded the updated MAPEI App, remember

the old one has to be deleted and the new one installed.

With membranes, cables and thermostats, the Mapeheat

product family offers the most comprehensive, customizable

line of radiant floor-heating solutions on the market.

Got questions? Get answers.

MAPEI's new FAQ tool answers your most common – and uncommon – questions.

Planiseal CR1 cold-fluid-applied waterproofing receives Miami-Dade NOA approval for:

NEW! UltraCare® Grout Refresh™ Calculator

Renovate and renew – or even completely change – your grout’s color with ease and the right amount of grout colorant using this easy-to-use product calculator.

Mapeguard® UM 35

Reshaping the Industry

Uncoupling, crack-isolation and waterproofing membrane

The world of MAPEI in your hands. If you have not

already downloaded the updated MAPEI App, remember

the old one has to be deleted and the new one installed.

With membranes, cables and thermostats, the Mapeheat

product family offers the most comprehensive, customizable

line of radiant floor-heating solutions on the market.

Realtà MAPEI North America Magazine

Read about the latest building projects, industry standards, technical information, product information (including correct application tips), market news, current events, conferences, educational seminars and more!

Projects

N° 37 - 10/18/2023

Planiseal CRI used to waterproof condominium parking garages

Planiseal CRI used to waterproof condominium parking garages

Projects Sustainability Architecture Social Responsibility

N° 37 - 10/18/2023

The combined transformative power of advanced construction materials and cutting-edge technology is evident in the collaboration between MAPEI’s Planitop 3D ink/mortar and Black Buffalo 3D Corporation’s NEXCON printers. Together, they have been…

The combined transformative power of advanced construction materials and cutting-edge technology is evident in the collaboration between MAPEI’s Planitop 3D ink/mortar and Black Buffalo 3D…

Projects

N° 37 - 10/18/2023

MAPEI setting materials are used throughout the popular and busy Scott Aquarium at the Omaha Zoo

MAPEI setting materials are used throughout the popular and busy Scott Aquarium at the Omaha Zoo

Topical news, references, insights and our commitment to art, culture and sports and much more in the latest issue of Realtà MAPEI.

Sustainability is part of everything we do

Technical Services at 1-800-992-6273

Customer Service at 1-800-426-2734 (1-800-42-MAPEI)